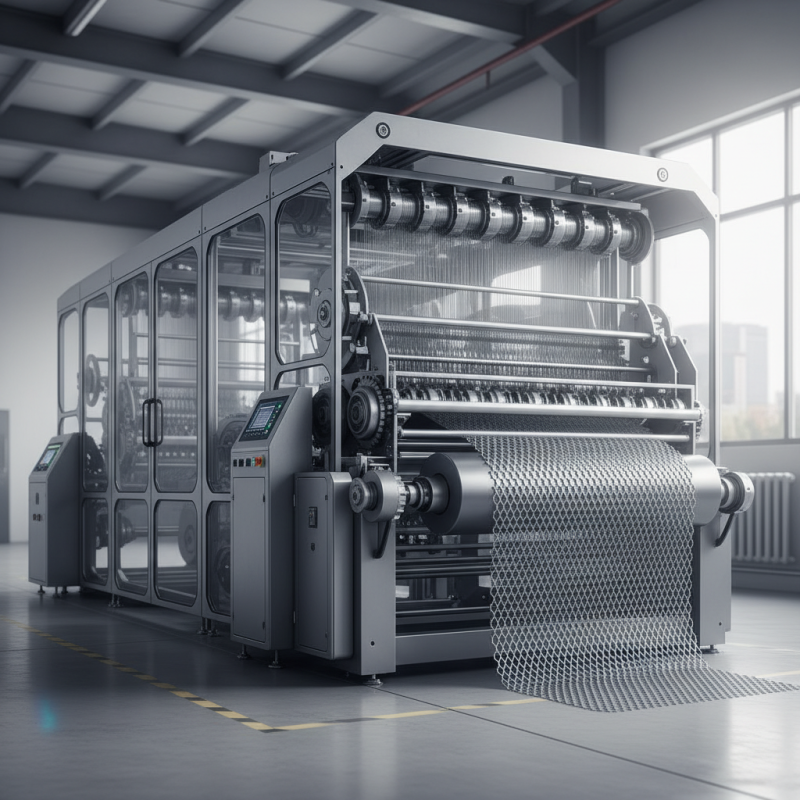

2026 Best Wire Mesh Weaving Machine Features and Benefits?

The wire mesh weaving machine industry is evolving rapidly. According to a recent report by MarketsandMarkets, the global market is projected to grow by 5.7% annually until 2026. These machines play a vital role in various sectors, including construction, agriculture, and manufacturing. As technology advances, the features and benefits of these machines become increasingly significant.

Expert John Smith, a leading figure in wire mesh manufacturing, states, “The efficiency of a wire mesh weaving machine can drastically improve production rates.” This highlights the importance of investing in high-quality machines. Today's equipment offers features such as automated weaving, advanced pattern customization, and enhanced durability. However, challenges remain. Many manufacturers struggle to keep pace with new technology, which can hinder growth.

The need for innovation pushes this industry forward. Manufacturers must reflect on how to incorporate new features while ensuring ease of use. Balancing cutting-edge technology with traditional weaving techniques is essential. In an ever-competitive market, the wire mesh weaving machine continues to be a crucial asset for those who adapt and evolve.

Overview of Wire Mesh Weaving Machines in 2026

In 2026, wire mesh weaving machines are at the forefront of manufacturing technology. These machines have evolved to meet increasing industry demands. A recent industry report indicates that the global wire mesh market is projected to reach USD 25 billion by 2026. This growth emphasizes the need for efficient production processes.

Modern machines now incorporate advanced control systems. These interfaces simplify operation, reducing the learning curve for new users. Additionally, automation features enhance speed and accuracy. Research by industry analysts found that automated machines can increase production efficiency by up to 30%. Yet, not all companies have adopted these technologies; many still use outdated systems, risking lower output and operational inefficiencies.

Despite advancements, challenges remain. Not every weaving machine can handle diverse wire types and sizes effectively. Flexibility in design is crucial. A machine that struggles with smaller diameter wires can limit a factory's product range. As the market evolves, businesses need to reconsider their equipment choices. They must stay adaptable to thrive in a competitive landscape. Investing in the right technology is vital for long-term success.

Key Features of the 2026 Wire Mesh Weaving Machines

The 2026 Wire Mesh Weaving Machines come with a range of innovative features. These machines ensure precision and efficiency in mesh production. They are built to handle various wire types with ease. The responsive controls allow for quick adjustments. This adaptability is crucial for different project requirements. Ergonomically designed, they reduce operator fatigue. This leads to smoother workflows in busy environments.

Tip: Regular maintenance is key. Check for wear and tear frequently. This helps maintain optimal performance and extends the machine's lifespan.

Another highlight is the enhanced automation features. These allow for higher output rates. Users can expect consistent quality with minimal manual intervention. A user-friendly interface simplifies the training process for new operators. This can save time and resources.

Tip: Document changes made during operations. Keeping a log can help troubleshoot issues later. It promotes a better understanding of machine performance.

Despite the advanced technology, challenges may arise. For instance, settings can sometimes be too complex. Operators may need extra time to familiarise themselves. Mistakes in configurations can lead to inconsistencies. Continuous learning is essential to master these machines.

Benefits of Using Advanced Wire Mesh Weaving Technology

Advanced wire mesh weaving technology offers significant benefits across various industries. This technology enables the production of high-quality wire mesh with enhanced durability. The precision of modern weaving methods results in tighter mesh patterns, which improve strength and resilience. Users often notice a reduction in material waste due to efficient production processes.

The ability to customize mesh specifications is another crucial advantage. For instance, different thicknesses and mesh sizes can be tailored to specific applications. This flexibility leads to better performance in applications, from construction to filtration. However, technology does come with its challenges. Some operators may struggle to master new machinery. Training is essential to unlock the full potential of these machines.

Efficiency in production is a key benefit that cannot be overlooked. Advanced machines can operate at higher speeds, producing more mesh in less time. This increased output can significantly enhance profitability. Yet, it’s important to maintain machine condition to ensure longevity. Regular maintenance might be overlooked, leading to operational issues. Investing in this technology can lead to a better return, but companies must remain vigilant.

Comparative Analysis of Leading Wire Mesh Weaving Brands

When analyzing leading wire mesh weaving brands, several key features stand out. Durability is often highlighted. Machines that withstand heavy use tend to attract more positive reviews. However, some brands overlook maintenance needs. Regular upkeep can be a hassle. It’s an area where brands must improve.

Efficiency is another critical consideration. Many machines boast high production rates, but real-world performance can vary. Users often report differences in output based on material types. The setup process can also be cumbersome. If a machine takes too long to prepare, it can impact productivity. Features like easy calibration are necessary.

Design flexibility is important for modern applications. Brands that offer customizable settings provide a significant advantage. However, navigating these options can be confusing. Not all machines come with user-friendly interfaces. An intuitive design is essential for optimal operation. Performance features must align with user needs while remaining accessible.

Future Trends in Wire Mesh Weaving Machine Development

The wire mesh weaving machine industry is evolving rapidly. Future trends show an increased focus on automation and smart technology. According to a recent market report, automation is projected to enhance production efficiency by 30% in the next five years. This shift could streamline operations and reduce labor costs.

Moreover, sustainable practices are gaining traction in machine development. A significant portion of manufacturers is investing in eco-friendly materials. Reports indicate that nearly 40% of industry players plan to incorporate recycled materials by 2026. However, challenges remain. Adapting traditional machines to accommodate new technologies can be costly.

The integration of AI in weaving processes is also notable. This advancement could support precision and reduce material waste. Researchers predict a 25% decrease in errors with AI implementation. But not all companies are prepared for this transition. Many face a skills gap in understanding AI technologies. Balancing innovation with practical expertise will be crucial for future success.