Unlocking Efficiency: The Advantages of the Best Automatic Assembly Machine

In today's fast-paced manufacturing landscape, the significance of an Automatic Assembly Machine cannot be overstated. With the global assembly automation market projected to reach $200 billion by 2026, driven by the need for enhanced productivity and reduced labor costs, these machines are increasingly becoming a focal point for manufacturers looking to optimize their operations. According to a report by Technavio, the adoption rate of automated assembly solutions has surged by 32% over the past three years, highlighting a robust shift towards mechanization. This shift not only leads to substantial time savings but also improves accuracy and reduces operational errors. As companies strive to remain competitive, understanding the advantages of investing in the best automatic assembly machines becomes paramount for unlocking efficiency and sustaining growth in an era characterized by rapid technological advancements.

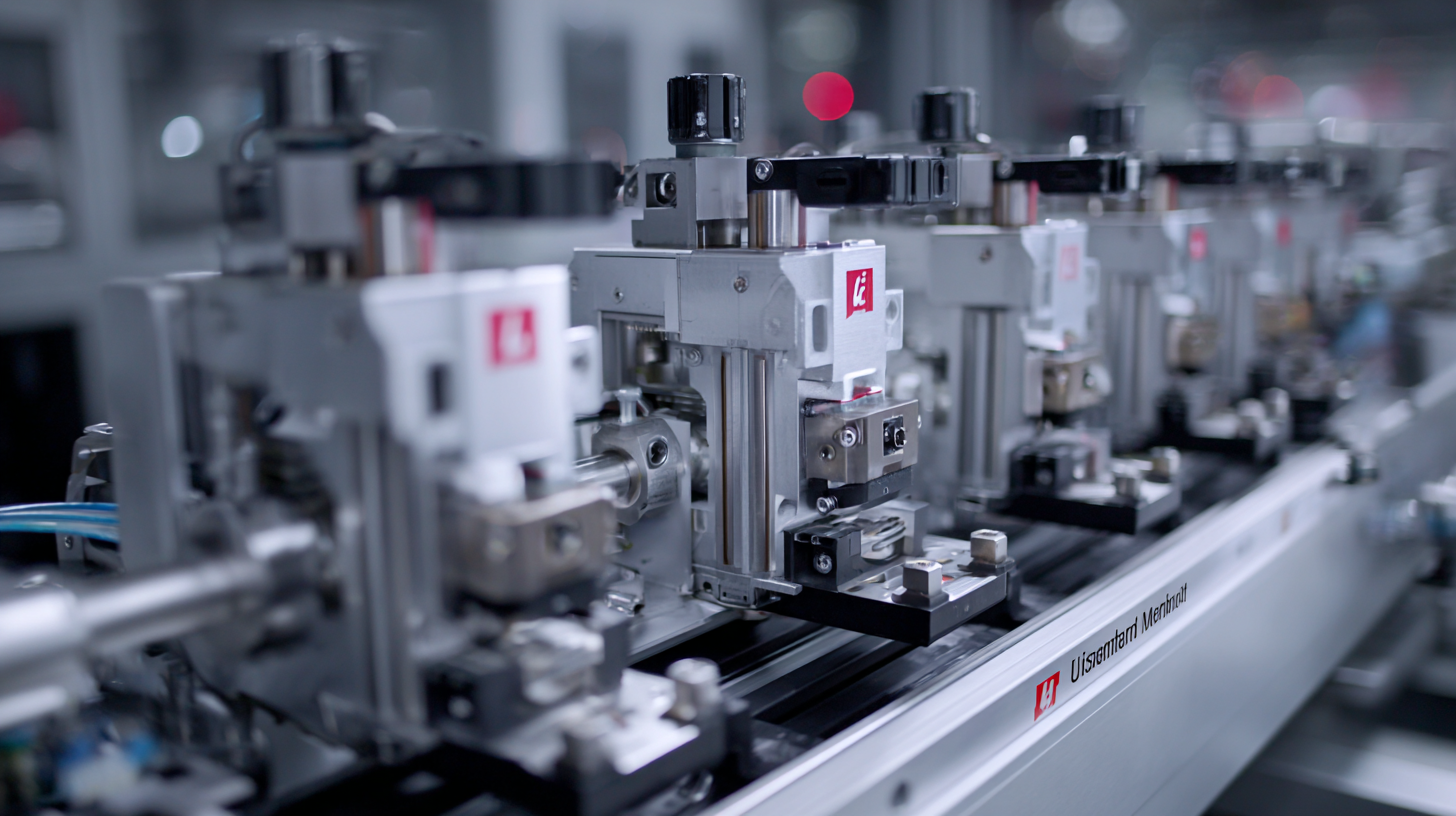

Key Technical Specifications of Top Automatic Assembly Machines

Automatic assembly machines have transformed manufacturing processes by enhancing efficiency and precision. According to a recent report by MarketsandMarkets, the global market for automatic assembly equipment is expected to grow from $12.5 billion in 2021 to over $20 billion by 2026, reflecting a compound annual growth rate (CAGR) of 10.6%. This surge underscores the increasing adoption of automation technologies in industrial settings.

When considering the technical specifications of the best automatic assembly machines, factors such as speed, accuracy, and flexibility are paramount. Leading models typically operate at speeds exceeding 300 parts per minute, while maintaining tolerances as tight as 0.01 mm. Additionally, the integration of advanced software for real-time monitoring and data analytics has become standard, allowing manufacturers to optimize operations and reduce downtime significantly. Research from IHS Markit highlights that companies employing high-quality assembly machines report a 30% increase in productivity and a 20% reduction in operational costs. These specifications illustrate the critical role of cutting-edge technology in achieving manufacturing excellence.

Unlocking Efficiency: The Advantages of the Best Automatic Assembly Machine

| Model | Production Speed (Units/Min) | Max Assembly Size (mm) | Power Consumption (kW) | Automation Level | Control System |

|---|---|---|---|---|---|

| Model A | 60 | 500 x 500 | 1.5 | Fully Automated | PLC-based |

| Model B | 80 | 600 x 400 | 2.0 | Semi-Automated | Touchscreen |

| Model C | 50 | 700 x 300 | 1.2 | Fully Automated | Computer-based |

| Model D | 70 | 800 x 500 | 1.8 | Semi-Automated | Remote Access |

Innovative Features that Enhance Production Efficiency

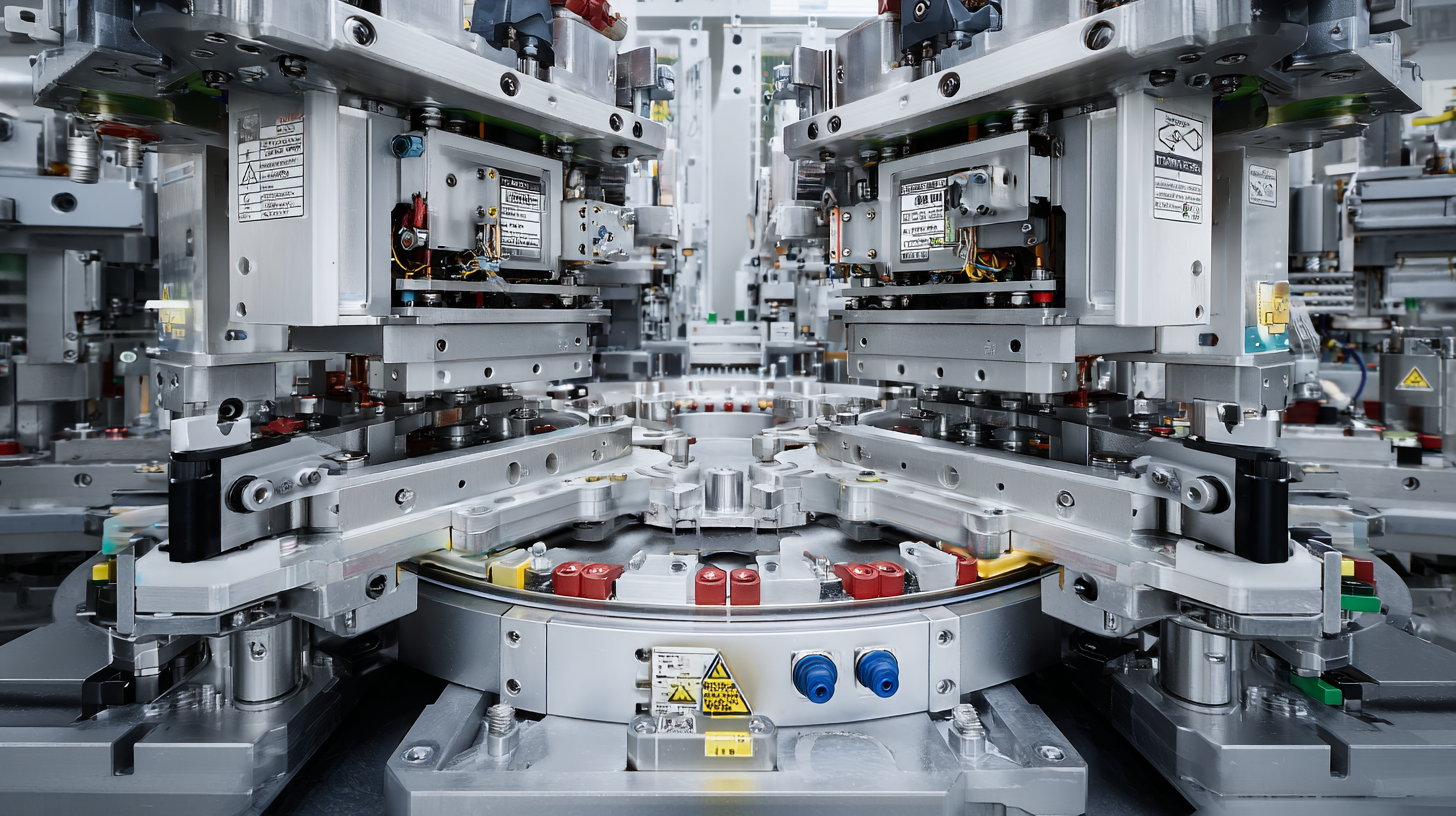

The rise of automated assembly machines is transforming the manufacturing landscape, prominently enhancing production efficiency through innovative features. According to a report by Grand View Research, the global market for automated assembly machines is expected to reach $68.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.3%. This growth highlights the sector's transition towards advanced automation to meet the increasing demand for precision and speed in production lines.

The rise of automated assembly machines is transforming the manufacturing landscape, prominently enhancing production efficiency through innovative features. According to a report by Grand View Research, the global market for automated assembly machines is expected to reach $68.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.3%. This growth highlights the sector's transition towards advanced automation to meet the increasing demand for precision and speed in production lines.

One of the standout features of modern automatic assembly machines is their integration of Artificial Intelligence (AI) and Machine Learning (ML). These technologies enable machines to optimize their processes in real-time, dramatically reducing cycle times and minimizing errors. A study by McKinsey revealed that companies implementing automation solutions saw productivity improvements of 20-30%, underscoring the efficacy of incorporating intelligent systems into manufacturing workflows. Furthermore, adaptive robotics allow for greater flexibility in production, enabling machines to switch between tasks without the need for extensive reconfiguration, ultimately streamlining operations.

Incorporating advanced sensor technologies, these machines can also collect and analyze data continuously, offering manufacturers invaluable insights into their operations. A report from Deloitte indicates that data-driven decision-making can enhance operational efficiency by up to 15%. By harnessing the power of these innovative features, manufacturers can not only maximize efficiency but also ensure higher quality outputs, setting new benchmarks in the industry.

How to Choose the Right Automatic Assembly Machine for Your Needs

When choosing the right automatic assembly machine for your needs, it's essential to consider various factors that can significantly impact both efficiency and productivity. The rapid advancements in manufacturing technologies mean that today's automatic assembly machines are not only faster but also more adaptable to the changing demands of various industries, especially in sectors like automotive and electronics. Recent trends indicate a substantial increase in automotive production and sales in China, reflecting the industry's push for greater automation to meet high-volume demands. Selecting an assembly machine that integrates seamlessly with existing systems and supports the specific requirements of your production line is crucial.

Additionally, as the market for automatic assembly machines continues to expand—projected to reach a significant value in the coming years—understanding the specific features that align with your manufacturing goals is vital. This includes evaluating the machine's flexibility, compatibility with smart technologies, and the ability to handle various product types simultaneously. By focusing on these aspects, manufacturers can unlock new levels of efficiency and cost-effectiveness, ultimately driving success in a competitive environment.

Maximizing ROI: Cost-Benefit Analysis of Automatic Assembly Solutions

The integration of automatic assembly machines into modern manufacturing processes has revolutionized efficiency and productivity. Conducting a cost-benefit analysis reveals that, despite the initial investment, these machines often lead to significant long-term savings. They reduce labor costs and minimize human error, which can be costly and time-consuming to rectify. This enhanced accuracy not only streamlines the production line but also ensures that products meet quality standards consistently, ultimately safeguarding the company's reputation.

Moreover, the speed at which automatic assembly solutions operate plays a crucial role in maximizing return on investment (ROI). With the ability to execute repetitive tasks at a rapid pace, manufacturers can increase output without compromising quality. Over time, the reduction in cycle time translates to higher volume production, allowing businesses to meet market demands and capitalize on new opportunities. Additionally, as technology advances, these machines become even more versatile and capable, further enhancing their cost-effectiveness and making them a pivotal component in achieving sustained operational efficiency.

Unlocking Efficiency: Advantages of Automatic Assembly Machines

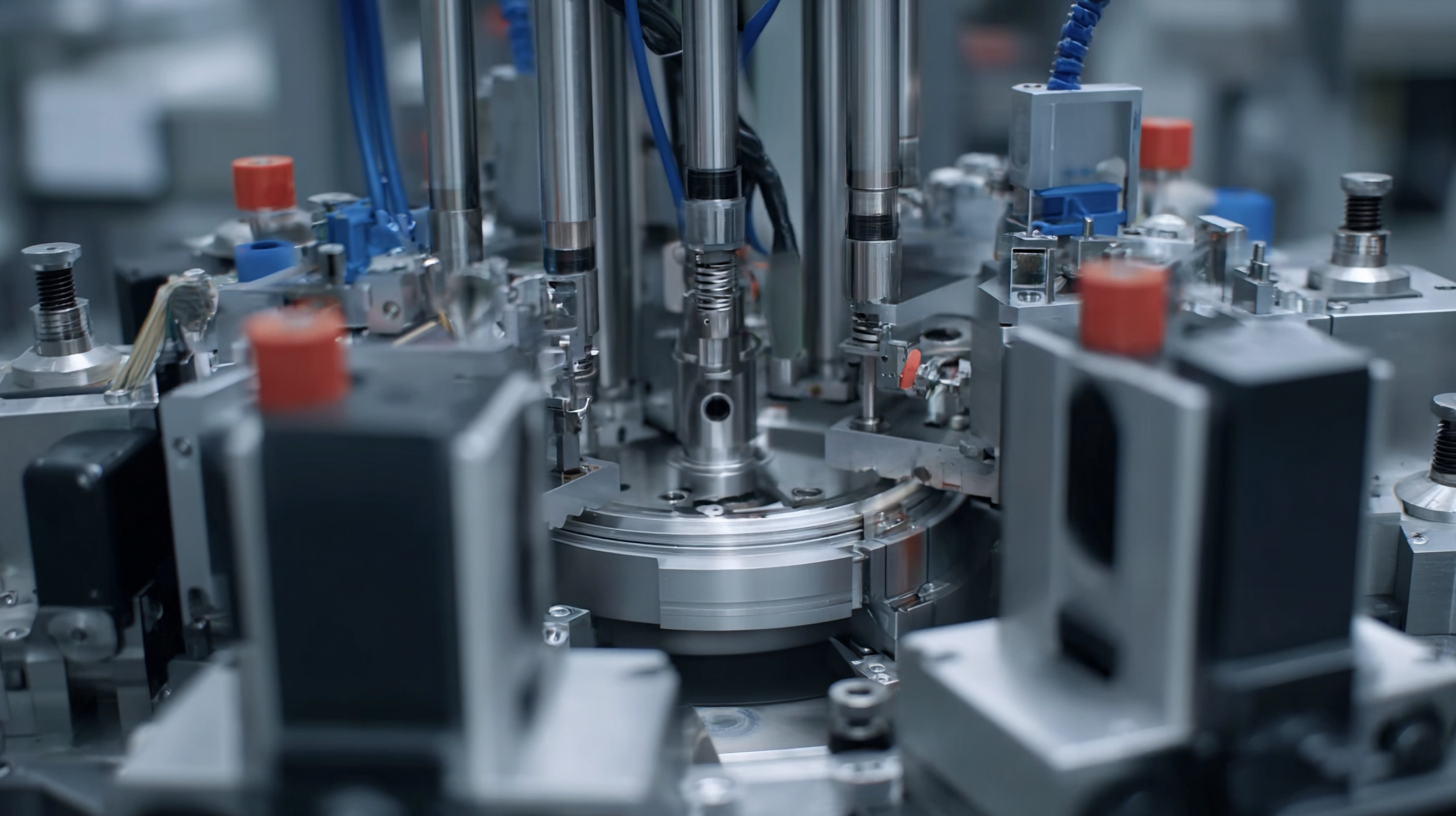

Maintenance Tips to Ensure Longevity of Your Assembly Machines

Regular maintenance is crucial for maximizing the durability and performance of your automatic assembly machines. One of the simplest yet effective tips is to establish a consistent cleaning routine. Dust and debris can accumulate over time, leading to mechanical failures and inefficient operation. By regularly inspecting and cleaning critical components such as conveyor belts and sensors, you can prevent potential breakdowns and ensure smooth functionality.

Another essential maintenance tip is to monitor and replace worn-out parts promptly. Components such as gears, bearings, and belts face wear and tear during continuous operation. By keeping a detailed log of parts performance and scheduling routine checks, you can identify signs of wear early and replace parts before they cause significant downtime. This proactive approach not only extends the life of the assembly machine but also enhances overall productivity in the long run.

Lastly, it's imperative to adhere to the manufacturer's maintenance schedule. Each automatic assembly machine comes with specific guidelines for maintenance and servicing that are crucial for optimal functionality. Following these recommendations helps to prevent unexpected issues and allows for the efficient operation of the machine, ensuring that your investment remains productive for years to come.