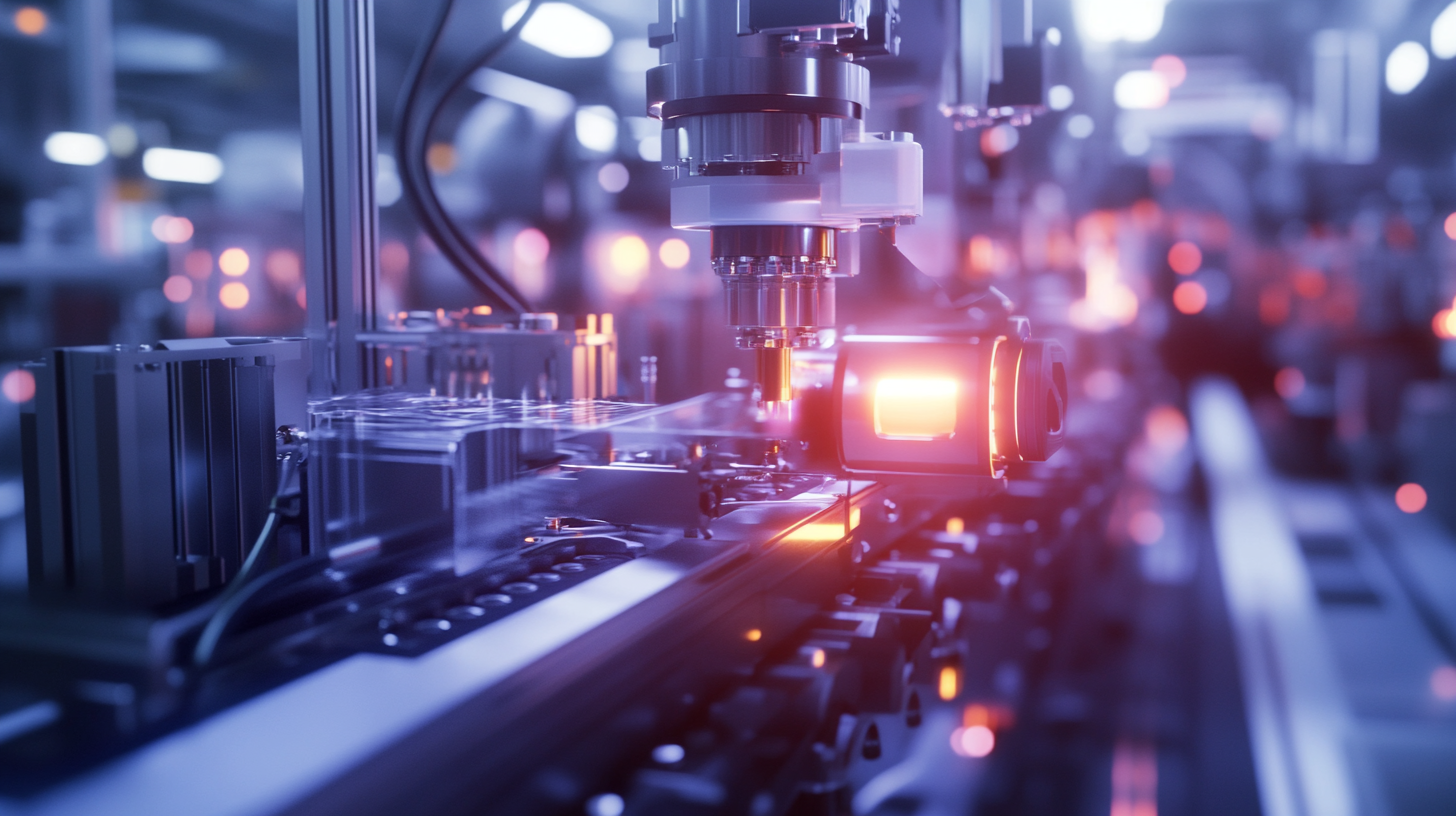

Advantages of Using the Best Assembly Machine for Your Production Line

In today's highly competitive manufacturing landscape, the integration of advanced technologies is crucial for enhancing production efficiency and quality. According to a report by Industry Insights, the global assembly machine market is projected to grow at a CAGR of 5.3% between 2021 and 2026, reaching a market value of $6 billion by the end of this period. This growth is driven by increasing demand for automation and the need for precision in various sectors, particularly in regions emphasizing "Made in China" quality improvements. The implementation of the best assembly machines not only streamlines production processes but also significantly enhances product reliability, thereby supporting Chinese manufacturers in meeting international standards. As companies strive for global competitiveness, leveraging advanced assembly machines becomes essential for achieving operational excellence and ensuring their products are well-positioned in the global marketplace.

Benefits of Enhanced Precision in Assembly Processes with Advanced Machines

In today’s competitive manufacturing environment, precision is paramount, and the best assembly machines are designed to enhance the accuracy of your production processes. Advanced assembly machines utilize cutting-edge technology that minimizes human error, ensuring that every component is placed and soldered with impeccable accuracy. This not only improves product quality but also helps in maintaining consistent production output, which is essential for meeting market demands.

**Tip:** Regularly calibrate and maintain your assembly machines to sustain their precision. Small adjustments can significantly impact overall performance, ensuring that your production line operates smoothly.

Moreover, enhanced precision leads to reduced waste and cost savings in the long run. When each component fits perfectly, the likelihood of defects decreases, which decreases rework and scrap rates. This not only optimizes resource usage but also contributes to a more sustainable manufacturing process.

**Tip:** Invest in training for your staff to understand the capabilities and maintenance routines of advanced assembly machines. A well-informed team can utilize these tools to their fullest potential, maximizing your production efficiency.

Improving Production Speed: How Top Machines Accelerate Workflow Efficiency

In today's competitive manufacturing landscape, improving production speed is more critical than ever. The latest advancements in assembly machines play a pivotal role in accelerating workflow efficiency. By optimizing machinery for rapid output, companies can significantly reduce turnaround times and enhance overall productivity. The integration of advanced technologies, such as AI-driven optimization and real-time analytics, enables these machines to adapt to varying production demands, ensuring that efficiency doesn’t compromise quality.

Moreover, the current technological trends indicate a strong push towards automation and data processing capabilities. As industries increasingly rely on data to drive innovation, the best assembly machines are equipped with features that facilitate seamless data collection and processing. This capability not only streamlines operations but also equips manufacturers with valuable insights, allowing for continuous improvement in their production lines.

By harnessing these state-of-the-art assembly machines, manufacturers can stay ahead of the curve, meeting the evolving needs of the market while maximizing their operational potential.

Cost Reduction: Analyzing Savings Through Automated Assembly Solutions

Automated assembly solutions have revolutionized the manufacturing sector, particularly when it comes to cost reduction. By integrating the best assembly machines into production lines, businesses can significantly streamline their operations. The upfront investment in these advanced machines often leads to substantial long-term savings. This is primarily due to the reduced labor costs, as fewer workers are needed to oversee the assembly process. Additionally, machines operate at a consistent speed and precision, minimizing errors and scrap rates, which further translates into savings on materials and rework.

Moreover, automated assembly solutions enhance production efficiency. With the capability to operate continuously, these machines maximize output, ensuring that production timelines are met without the delays commonly associated with human labor. This not only boosts productivity but also helps companies to fulfill orders more swiftly, thereby improving customer satisfaction and opening up new revenue opportunities. By analyzing the savings achieved through automation, it becomes evident that the strategic implementation of assembly machines not only slashes operational costs but also positions businesses for competitive advantage in an increasingly demanding market.

Increasing Product Quality: The Role of Advanced Assembly Machines in Minimizing Errors

Advanced assembly machines are revolutionizing production lines by significantly enhancing product quality and minimizing errors. According to a recent report by the International Society of Automation, implementing high-precision assembly technologies can decrease manufacturing defects by up to 30%. This reduction not only boosts customer satisfaction but also lowers costs associated with recalls and wasted materials, illustrating a direct correlation between advanced machinery and overall operational efficiency.

The role of these machines goes beyond simple automation; they incorporate sophisticated technologies like artificial intelligence and machine learning. Such advancements allow for real-time monitoring and adjustments during the assembly process. According to a study by the Institute for Advanced Manufacturing, companies that integrated smart assembly solutions reported a 25% increase in production accuracy. This heightened precision ensures that products meet stringent quality standards, ultimately enhancing brand reputation and marketability. As industries strive for excellence, investing in the best assembly machines emerges as a key strategy to optimize both quality and productivity.

Advantages of Using the Best Assembly Machine for Your Production Line - Increasing Product Quality: The Role of Advanced Assembly Machines in Minimizing Errors

| Feature | Description | Impact on Production |

|---|---|---|

| Precision | Advanced assembly machines use high-precision tools to ensure accurate component placement. | Reduces defects, leading to higher product quality and customer satisfaction. |

| Automation | Automated systems streamline the assembly process, minimizing human error. | Increases throughput and reduces labor costs while maintaining quality. |

| Flexibility | Modern machines can easily switch between different products and components. | Enhances the capacity to adapt to market demands and reduces downtime. |

| Data Integration | Machines can be integrated with data analytics systems for real-time monitoring. | Allows for proactive quality control and process optimization. |

| Safety Features | Incorporates safety mechanisms to protect operators and products. | Reduces the risk of accidents and product damages, ensuring consistent quality. |

Data-Driven Decision Making: Leveraging Analytics from the Best Assembly Machines

The integration of data-driven decision-making in manufacturing is transforming production lines, allowing businesses to leverage analytics for substantial advantages. As industries increasingly embrace digitalization and the principles of Industry 4.0, data analytics emerges as a critical driver of efficiency and innovation. A recent study highlights that over 70% of manufacturing leaders plan to invest in advanced analytics tools in the next two years. This trend underscores the pivotal role that comprehensive data insights play in operational optimization.

The application of advanced analytics from state-of-the-art assembly machines enables manufacturers to identify production bottlenecks, predict maintenance needs, and enhance overall workflow. For instance, companies utilizing real-time data reporting have reported a 25% increase in productivity and a significant reduction in waste by adopting more data-centric approaches. Furthermore, with the ongoing advancement of AI technologies, manufacturers are not only making informed decisions but are also capable of reimagining their processes—turning data into actionable insights that lead to improved quality and reduced costs. The smart factory of the future will rely heavily on these intelligent systems, making the best assembly machines an investment that pays dividends by driving efficiency and profit margins.