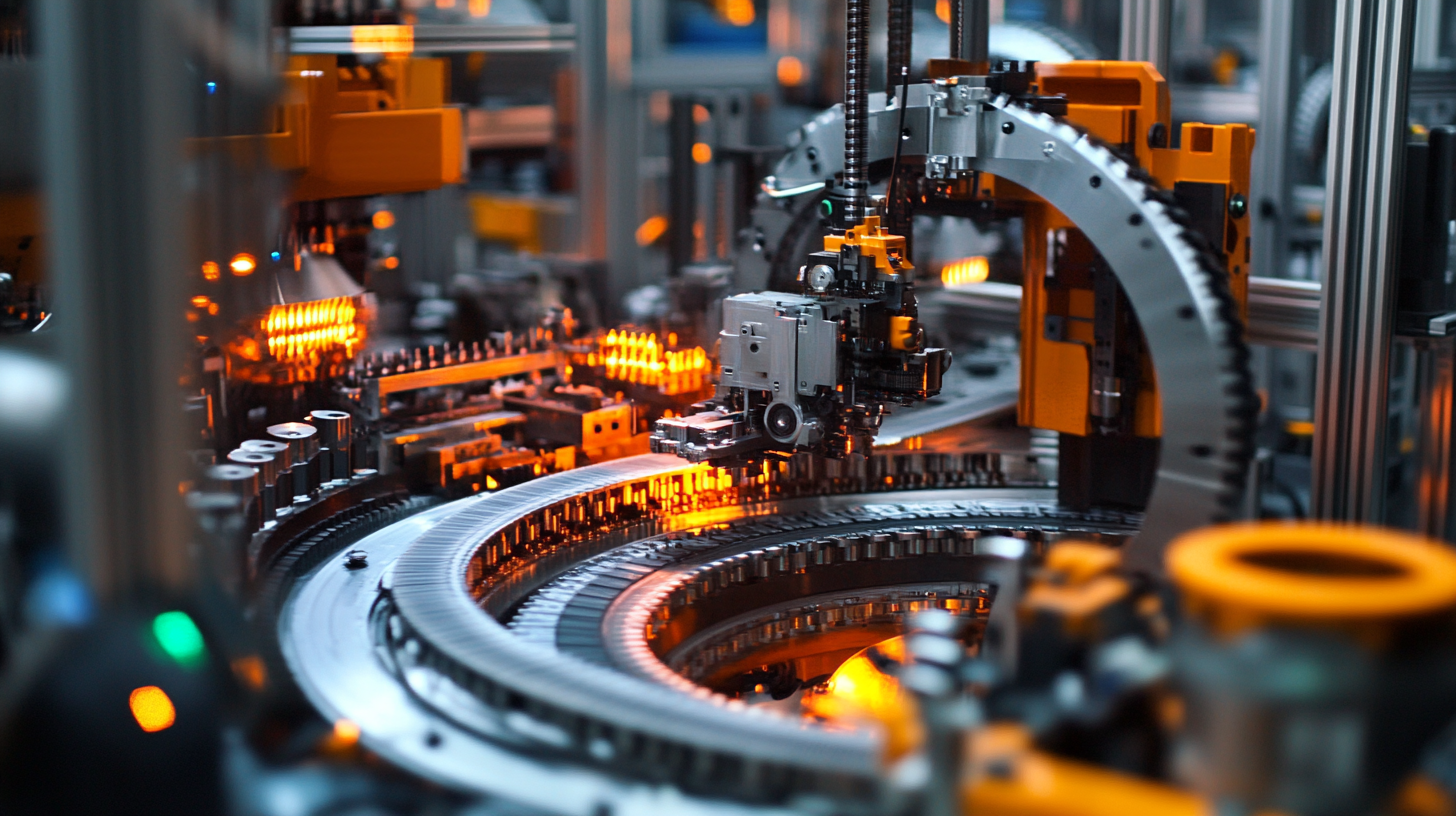

Innovative Examples of Best Automatic Assembly Machine Transforming Manufacturing Efficiency

In the rapidly evolving landscape of manufacturing, the integration of technology has become crucial for enhancing efficiency and productivity. One of the standout innovations making waves in this industry is the Automatic Assembly Machine. These machines are not just streamlining production processes; they are transforming the way products are assembled, leading to significant reductions in labor costs and time. By automating complex assembly tasks, manufacturers can achieve higher precision and consistency in their output, while also minimizing human error.

In this blog, we will explore the detailed technical parameters of various Automatic Assembly Machines, delving into how these advanced systems function and the best practices for implementing them in manufacturing settings. Join us as we uncover innovative examples that illustrate the remarkable impact of Automatic Assembly Machines on transforming manufacturing efficiency.

Challenges Facing the Implementation of Automatic Assembly Machines in Manufacturing

As manufacturers increasingly turn to automatic assembly machines to enhance efficiency, they encounter a set of unique challenges that can hinder their successful implementation. One of the primary obstacles is the significant upfront investment required for advanced machinery and technology integration. Many companies are wary of the initial costs, which can include not only the machines themselves but also the necessary upgrades to existing systems and infrastructure. This financial burden often leads businesses to delay or rethink their automation strategies.

Another challenge is the need for skilled personnel to operate and maintain these sophisticated machines. As technology evolves, the demand for workers with specialized knowledge in robotics and process automation continues to grow. Unfortunately, many companies struggle to find qualified candidates, limiting their ability to fully utilize automation’s potential. Additionally, employee resistance to change can create cultural barriers within organizations, making it difficult to promote a seamless integration of automatic assembly processes. Overcoming these hurdles is essential for manufacturers aiming to take full advantage of the increased productivity and efficiency that automatic assembly machines can provide.

The Impact of Machine Types on Production Line Efficiency and Flexibility

In today’s dynamic manufacturing landscape, the efficiency and flexibility of production lines are significantly influenced by the types of machines utilized. Automatic and semi-automatic liquid filling machines, for instance, are essential in enhancing operational throughput and reducing labor costs. The automatic machines, with their high-speed capabilities and precision, allow manufacturers to scale production effortlessly while maintaining high-quality standards. In contrast, semi-automatic machines offer operators the ability to control filling processes, catering to lower production volumes or varied product types, such as glass, plastic, and cartons.

The choice of filling technology also plays a vital role in overall efficiency. Techniques such as vacuum filling, volumetric filling, and weight filling have their unique advantages depending on the product characteristics and the desired accuracy. For instance, vacuum filling is ideal for foamy or fragile liquids, while volumetric filling can enhance precision for thicker substances. Manufacturers looking to optimize their production lines must carefully evaluate these factors to select the most appropriate equipment, ensuring they achieve the necessary balance between efficiency, cost, and product quality.

Common Issues with Integration of Automatic Assembly Machines into Existing Systems

Integrating automatic assembly machines into existing manufacturing systems can significantly boost efficiency, but it often comes with common integration challenges. According to a report by McKinsey, companies that successfully implement automation see productivity increases of 20-30%. However, many organizations struggle with the compatibility of new machinery with legacy systems, which can result in downtime and increased costs. In fact, a survey from Deloitte highlights that nearly 33% of manufacturers cite system integration as a primary obstacle when adopting automated solutions.

To alleviate some of these issues, manufacturers should prioritize thorough planning before implementation. A well-defined roadmap for integration can help mitigate unexpected complications. For instance, conducting a pilot program with automated solutions on a smaller scale can provide valuable insights, paving the way for smoother large-scale implementation.

Lastly, effective training for staff is crucial. Employees need adequate education on how to operate and troubleshoot the new systems. According to a report by PwC, 60% of organizations that invested in upskilling their workforce managed to realize the benefits of automation much more rapidly than those that did not. Empowering your team is a pivotal step in harnessing the full potential of automatic assembly technologies.

Cost-Benefit Analysis: Weighing Advantages Against Problems of Automatic Assembly Solutions

The integration of automatic assembly machines in manufacturing presents a compelling opportunity for cost savings and efficiency improvements. By streamlining production processes, these machines can significantly reduce labor costs and increase output. Companies are able to achieve higher precision and consistency, which minimizes waste and defects. Additionally, the scalability of automatic assembly solutions allows businesses to adapt to fluctuating market demands without compromising on quality.

However, transitioning to automated systems is not without its challenges. Initial investment costs can be substantial, and companies must carefully evaluate the return on investment over time. Problems such as equipment maintenance, potential job displacement, and the need for advanced technical skills among the workforce can pose significant hurdles. Conducting a thorough cost-benefit analysis becomes essential to understand how the advantages of automation, such as increased efficiency and reduced long-term costs, can be weighed against these potential issues. This balanced approach ensures that businesses make informed decisions in their pursuit of enhanced manufacturing processes.

Future Trends: Overcoming Current Limitations of Automatic Assembly Technologies in Manufacturing

The evolution of automatic assembly technologies is transforming the landscape of manufacturing, addressing many current challenges while paving the way for future advancements. According to a recent report by the International Federation of Robotics (IFR), the global market for industrial robots is projected to reach $70 billion by 2025, highlighting the immediate need for manufacturers to integrate innovative automation solutions. However, these technologies face significant limitations, including adaptability to varying production scales and the ability to manage complex product designs.

To successfully overcome these obstacles, manufacturers must consider investing in advanced machine learning algorithms and artificial intelligence that can enhance the flexibility of automatic assembly machines. A study from McKinsey indicates that companies adopting AI in production processes could improve productivity by up to 20%. Additionally, creating modularized assembly systems can help companies adapt to diverse manufacturing requirements without major overhauls.

**Tips:** To maximize the efficiency of your automatic assembly processes, prioritize investing in scalable robots that offer programmable features. Regularly assess your assembly line for potential AI integrations that could reduce downtime and streamline operations. Lastly, maintaining a collaborative environment between human operators and machines can lead to innovative solutions that enhance overall productivity.