2026 Best Stainless Steel Wire Mesh Types for Every Need?

In the world of industrial materials, "stainless steel wire mesh" stands out for its versatility and durability. Expert John Smith, a leading figure in the wire mesh industry, once said, "The right type of stainless steel wire mesh can transform a project’s success." This quote captures the essence of why understanding different types of stainless steel wire mesh matters.

With so many applications, choosing the right mesh can be confusing. For filtration, construction, or decorative uses, each type serves a unique purpose. Yet, selecting the best mesh shouldn't be rushed. Sometimes, it’s a trial-and-error process, requiring time to evaluate what truly works.

It's easy to overlook some parameters while making choices. For instance, the thickness of the wire, the weave pattern, and the resistance to corrosion are crucial factors. A little reflection can lead to better decisions. Instead of assuming one type fits all, companies should explore their specific needs. The journey to find the best stainless steel wire mesh is often imperfect but ultimately rewarding.

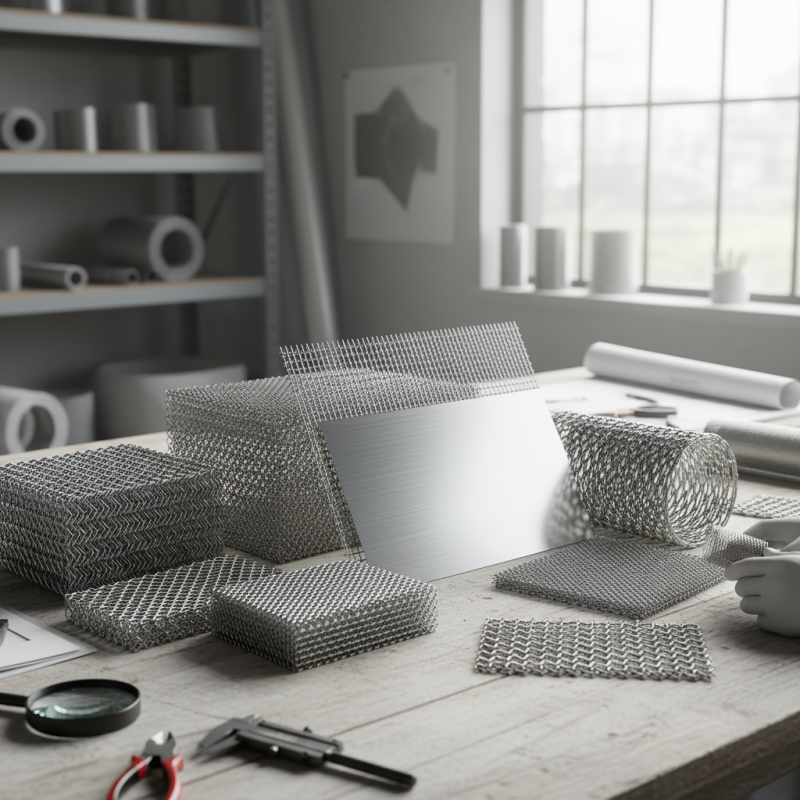

Types of Stainless Steel Wire Mesh and Their Unique Properties

Stainless steel wire mesh comes in various types, each serving unique purposes. The choice of mesh heavily depends on the intended application. For instance, welded wire mesh is known for its strength and structural integrity. It is commonly used in construction, reinforcing concrete, and in fences. The uniformity in spacing offers reliable support.

Another interesting type is woven wire mesh. This type provides flexibility and is preferred in filtration applications. The various weave styles allow for different levels of openness and strength. From heavy-duty applications to more delicate uses, woven wire mesh caters to diverse needs.

There's also expanded metal mesh, which is distinct in design. It’s made by cutting and stretching, creating a unique, diamond-shaped opening. This type is lightweight but still very strong. It is perfect for architectural applications and walkways. However, one must consider the thickness and gauge carefully since they affect durability. Exploring these types can be overwhelming, but recognizing their features is essential for making the right choice.

Applications of Stainless Steel Wire Mesh Across Different Industries

Stainless steel wire mesh serves various industries, showcasing its versatility and functionality. In construction, it reinforces concrete structures. This mesh can improve the strength of floors and walls. It resists rust and corrosion, which is crucial for durability. Additionally, mesh panels create secure environments on building sites. However, access to quality materials can sometimes lead to issues. Ensuring the right thickness and weave is essential.

In the food and beverage industry, stainless steel wire mesh plays a vital role. It filters liquids and solids during production. The fine mesh retains small particles while allowing flow. In addition, it helps maintain hygiene standards, which are paramount in this sector. However, improper cleaning can lead to contamination risks. Regular maintenance is essential to uphold safety.

Moreover, the medical industry benefits significantly from the use of stainless steel mesh. It is used in surgical applications and equipment. The non-reactive nature of stainless steel minimizes infection risk. Some might overlook the importance of using proper mesh for specific surgeries. Ensuring compatibility with medical devices can be challenging but is necessary for patient safety.

Factors to Consider When Choosing Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, several key factors should guide your decision. The intended application significantly impacts the type of mesh you'll need. For instance, architectural uses often require aesthetic appeal, while industrial applications demand strength and durability. A recent industry report revealed that heavy-duty wire mesh is preferred in construction, with about 60% of professionals opting for higher tensile strength.

Another critical aspect is the mesh size or wire diameter. A smaller aperture may be necessary for filtration, but it can restrict airflow and create pressure drop issues. The appropriate balance is essential. According to a 2023 study, over 38% of users faced challenges with inadequate filtration performance, primarily due to incorrect mesh choices. This shows the importance of thorough research.

Corrosion resistance is also vital. Stainless steel grades vary in their resistance to different environments. For example, Type 304 is common, but Type 316 offers better performance in harsh coastal areas. Around 45% of users still selected materials without considering environmental factors. This choice often led to premature degradation, raising costs. Thus, understanding your material's specific properties is crucial for long-term performance.

Comparison of Various Grades of Stainless Steel for Wire Mesh

When choosing stainless steel wire mesh, understanding the various grades is key. The most common grades include 304 and 316. Grade 304 is widely used due to its excellent corrosion resistance and flexibility. It contains 18% chromium and 8% nickel. Meanwhile, Grade 316 offers better protection against chloride environments, containing 16% chromium, 10% nickel, and 2% molybdenum. This makes it more suitable for coastal applications.

Data from the international stainless steel forum suggests that 304 remains the most popular grade, making up about 60% of all stainless steel production. However, users often overlook that while 316 is pricier, its longevity in harsher environments may save costs in the long run. The choice largely depends on specific application needs.

Some applications demand features like high strength or heat resistance. Grade 410 offers better wear resistance thanks to its higher carbon content but lacks the corrosion resistance of 304 and 316. This compromise may not suit every need. Users need to balance performance with costs, making informed choices essential. Thus, selecting the appropriate stainless steel grade involves careful consideration and sometimes, a bit of trial and error.

2026 Best Stainless Steel Wire Mesh Types for Every Need

| Wire Mesh Type | Grade | Mesh Size (Inches) | Application | Corrosion Resistance |

|---|---|---|---|---|

| Welded Wire Mesh | 304 | 0.25 | Fencing & Security | Moderate |

| Expanded Metal Mesh | 316 | 0.5 | Filtration & Grating | High |

| Woven Wire Mesh | 304L | 0.125 | Sifting & Screening | Moderate |

| Square Wire Mesh | 430 | 0.063 | Decorative Limitation | Low |

| Dutch Weave Mesh | 316L | 0.10 | Oil & Gas | Very High |

Maintenance and Care Tips for Stainless Steel Wire Mesh Products

Maintaining stainless steel wire mesh is crucial to prolong its lifespan. Regular cleaning helps remove dirt and grime. Use mild soap and warm water for routine cleaning. Avoid harsh chemicals, as they may cause damage. Rinse thoroughly to prevent residue buildup.

Inspect your wire mesh frequently. Look for signs of wear or damage. Small tears can become bigger if not addressed. Pay attention to rust spots. While stainless steel is resistant, it’s not immune to corrosion. If you spot rust, act quickly. Sand it down and apply a suitable treatment.

Storage matters too. Keep the mesh in a dry, well-ventilated area. Humidity can lead to issues over time. If you’re using it outdoors, cover it during harsh weather. This step can minimize exposure to elements. Careful handling is essential. Dropping or bending can compromise its integrity. Reflect on your practices regularly to ensure you’re doing the best for your mesh.