Top 10 Essential Phone Testing Equipment for Quality Assurance Professionals

As the mobile technology landscape continues to evolve at an unprecedented pace, ensuring the quality and reliability of devices has never been more critical. In this context, phone testing equipment plays an essential role in the quality assurance processes that underpin successful product launches. Renowned industry expert Dr. Emily Chen, a leader in mobile device testing at Tech Innovations Inc., once stated, "The right phone testing equipment is not just about detecting flaws; it's about ensuring the user experience and safety of every device before it hits the market."

In the pursuit of excellence, quality assurance professionals must be equipped with the latest and most effective testing tools to thoroughly evaluate every aspect of mobile devices. From performance analysis and durability testing to compliance assessments, the top 10 phone testing equipment tools identified for 2025 are designed to meet the rising demands of both manufacturers and consumers. This article delves into these vital tools, shedding light on their significance in maintaining high standards in the phone industry and how they empower quality assurance professionals to deliver outstanding results. As we explore the landscape of phone testing equipment, understanding their functionality and application will pave the way for enhanced device reliability and user satisfaction.

Key Features to Look for in Phone Testing Equipment

When selecting phone testing equipment, quality assurance professionals should focus on several key features to ensure reliable performance and accurate results. Firstly, the equipment must support multiple operating systems and device types, as today's smartphones come in various brands and functionalities. This versatility enables testers to evaluate how apps and functions perform across different scenarios, which is essential for comprehensive quality assurance.

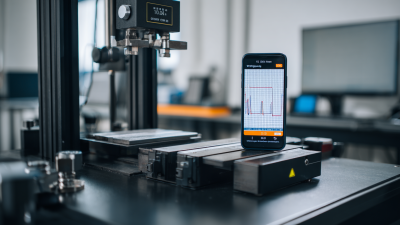

Another crucial feature is the ability to simulate real-world conditions. Look for equipment that provides capabilities for stress testing, environmental simulations, and network condition alterations. These features allow for thorough assessments under various usage conditions, ensuring that the phones can withstand everyday challenges faced by users.

**Tips:** Always consider equipment that offers automation capabilities to streamline testing processes. Automation reduces human error and accelerates the testing process significantly. Additionally, prioritize tools that provide detailed reporting and analytics, as this will help teams make informed decisions based on the data collected during testing. Investing time to find the right equipment can save resources and improve the overall quality of the final product.

Importance of Quality Assurance in Mobile Device Development

Quality assurance (QA) plays a pivotal role in mobile device development, ensuring that applications meet both user expectations and regulatory standards. As mobile accessibility becomes essential for businesses, it is crucial for QA professionals to employ robust testing tools and practices. According to industry reports, mobile accessibility directly influences customer satisfaction and retention, highlighting the need for thorough testing. In 2025, custom mobile application development costs are expected to average around $171,450, emphasizing the financial stakes involved in delivering high-quality software. Investing in effective QA practices can mitigate the risks associated with costly app development failures.

Moreover, as technology continues to evolve, QA engineers must enhance their skill sets to address emerging challenges. Research indicates that exceptional problem-solving and critical thinking skills are vital for identifying issues and implementing solutions effectively. Anticipating the complexities of device fragmentation and platform inconsistencies, QA professionals must adopt best practices such as early testing and automation, which are projected to raise software quality. Implementing advanced testing solutions not only boosts project management but also fosters innovation, ensuring businesses remain competitive in an increasingly mobile-centric market.

Essential Tools for Functional Testing of Smartphones

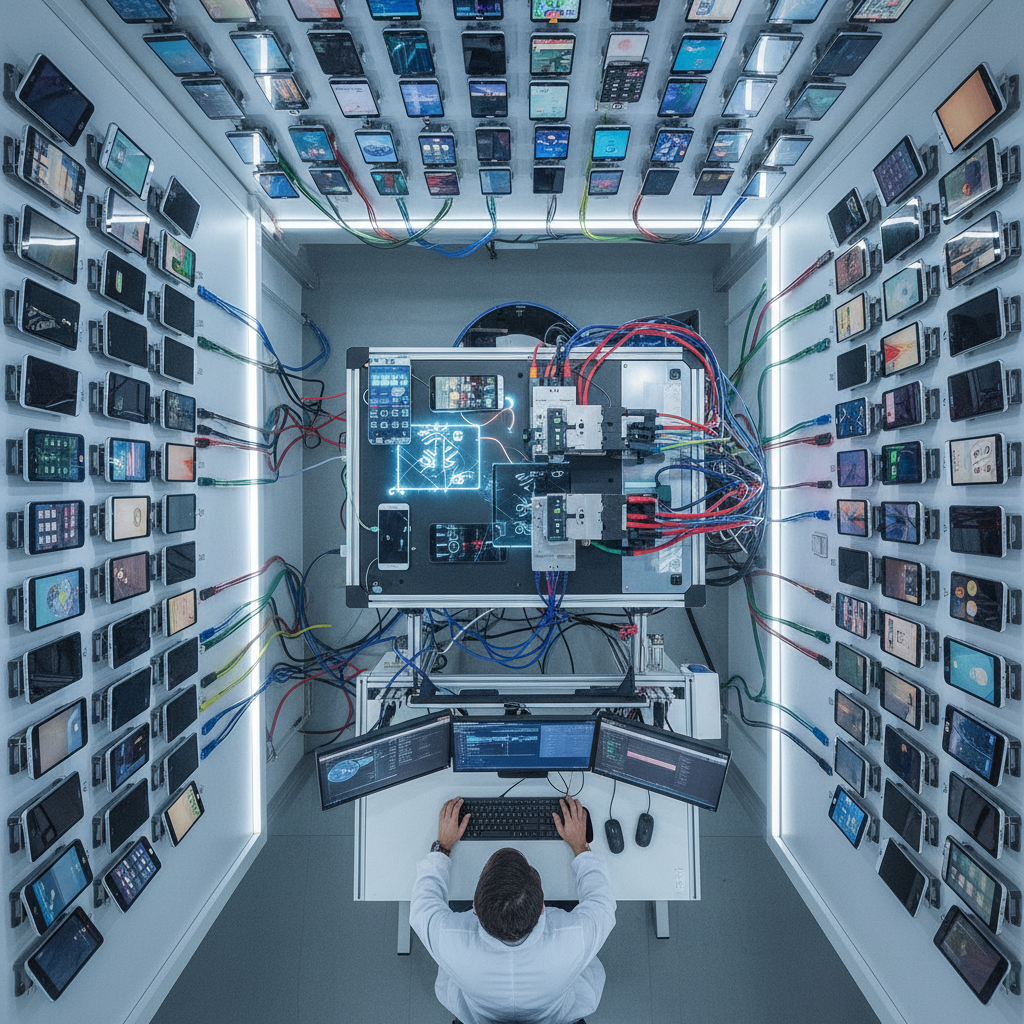

When it comes to ensuring the functionality of smartphones, quality assurance professionals rely on a variety of essential tools designed to streamline the testing process. One of the most critical pieces of equipment is the automated testing platform, which allows for comprehensive regression testing. These platforms are capable of executing multiple test cases simultaneously, significantly reducing the time needed to detect bugs and performance issues.

Additionally, mobile device labs equipped with a wide range of devices help testers to evaluate the smartphone’s performance across different operating systems and hardware variations.

Another indispensable tool is the performance testing software, which enables QA teams to assess the responsiveness, speed, and overall user experience of a smartphone application. Coupled with connectivity testing tools, which evaluate the device’s ability to maintain consistent connections across various networks, these tools provide a complete picture of a smartphone’s functional reliability.

Moreover, specialized hardware for stress testing can simulate high usage scenarios, allowing QA professionals to identify potential failures before they impact end-users. By leveraging these essential tools, quality assurance teams can ensure that smartphones meet rigorous functional standards.

The Role of Software Testing Tools in Ensuring Performance

Software testing tools play a crucial role in ensuring the performance and reliability of mobile phones. These tools allow quality assurance professionals to conduct rigorous testing throughout the development cycle, identifying potential issues before they reach the consumer. Automated testing frameworks, for instance, enable teams to run a suite of tests efficiently, simulating various scenarios that a device might encounter in real-world usage. This not only saves time but also provides consistent results that can be vital for maintaining high standards.

In addition to automation, performance monitoring tools are essential in assessing how a mobile phone behaves under different conditions. They provide insights into resource consumption, responsiveness, and overall user experience. By leveraging these tools, QA professionals can pinpoint bottlenecks and optimize software performance, ensuring that applications run smoothly on various devices. The integration of analytics into testing processes further empowers teams to make data-driven decisions, enhancing the stability and functionality of mobile phones before they hit the market.

Top 10 Essential Phone Testing Equipment for Quality Assurance Professionals

Comparing Cost-Effective Solutions for Phone Testing Equipment

When it comes to ensuring quality in phone manufacturing, selecting the right testing equipment can significantly impact both performance and cost-effectiveness. A recent industry report highlights that effective testing can reduce defect rates by up to 30%. Professionals need to weigh their options carefully, especially with the rising costs of production materials. Investing in cost-effective testing equipment can streamline operations and enhance product reliability without breaking the bank.

One essential tip for quality assurance professionals is to prioritize equipment that offers multi-functional capabilities. For instance, devices that combine audio, visual, and connectivity tests can save both time and budget. According to studies, organizations that utilize integrated testing solutions see about 20% faster turnaround times, allowing for a more agile response to market demands.

Additionally, professionals should consider the longevity and support offered by the equipment manufacturers. Equipment that provides long-term reliability and available technical support can save significant costs in the long run. Reports indicate that 70% of issues arise post-deployment due to inadequate testing; therefore, investing in durable and well-supported equipment is crucial. Choose wisely, and your testing operations will not only be cost-effective but also more efficient.

Top 10 Essential Phone Testing Equipment for Quality Assurance Professionals

| Equipment | Function | Cost (USD) | Portability | Ease of Use |

|---|---|---|---|---|

| Multimeter | Electrical testing | 50 | Portable | Easy |

| Thermal Camera | Heat analysis | 400 | Moderate | Moderate |

| Signal Analyzer | Signal quality | 2500 | Non-portable | Challenging |

| Network Tester | Connectivity tests | 300 | Portable | Moderate |

| Power Supply Tester | Battery health | 150 | Portable | Easy |

| Audio Analyzer | Speaker quality | 800 | Non-portable | Challenging |

| Camera Tester | Camera quality | 700 | Portable | Easy |

| Vibration Tester | Durability tests | 1200 | Non-portable | Challenging |

| Water Resistance Tester | Seal quality | 1500 | Portable | Moderate |

| Char Tool | Performance testing | 100 | Portable | Easy |

Related Posts

-

The Ultimate Guide to Choosing the Best Phone Testing Equipment for Your Needs

-

How to Optimize Your Phone Testing Equipment for Accurate Performance Metrics

-

Understanding the Importance of Accurate Meter Test Equipment for Efficient Energy Management

-

Ultimate Guide to Choosing the Best Ball Rebound Tester for Your Needs

-

Water Testing Meter Innovations and Market Trends at the 138th Canton Fair in 2025

-

What is Field Test Equipment and How It Benefits Your Testing Process