The Definitive Ultimate Guide to Choosing the Best Assembly Machine for Your Factory Needs

In today's rapidly evolving manufacturing landscape, making informed decisions about your factory's equipment is crucial for maintaining competitiveness and efficiency. One of the most significant investments you can make is in an Assembly Machine, which plays a vital role in streamlining production processes and enhancing product quality. As China continues to solidify its position as a global manufacturing powerhouse, understanding the nuances of selecting the right Assembly Machine becomes essential for businesses looking to expand their export footprints. This guide will walk you through the key considerations and features to assess when selecting an Assembly Machine that meets your unique factory needs, ensuring that your manufacturing operations not only thrive domestically but also succeed on the international stage.

Understanding the Importance of Assembly Machines in Modern Manufacturing Efficiency

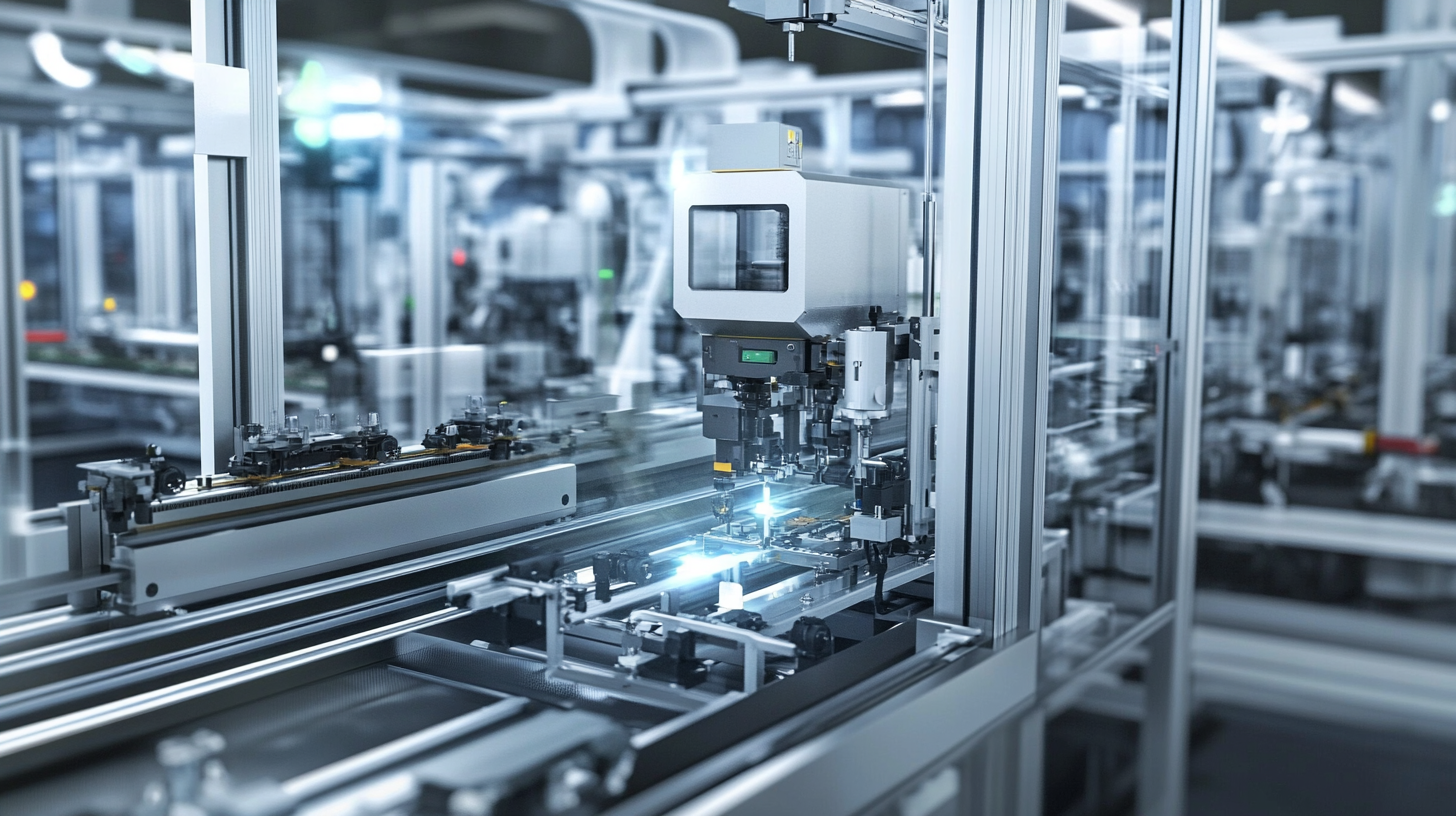

In today’s competitive landscape, the significance of assembly machines in enhancing manufacturing efficiency cannot be overstated. These machines serve as the backbone of modern production lines, enabling factories to increase their output while maintaining high-quality standards. With the pressure to meet consumer demands swiftly, assembly machines streamline operations by automating repetitive tasks and reducing human error. This not only accelerates the manufacturing process but also frees up skilled workers to focus on more complex operations that require critical thinking and creativity.

In today’s competitive landscape, the significance of assembly machines in enhancing manufacturing efficiency cannot be overstated. These machines serve as the backbone of modern production lines, enabling factories to increase their output while maintaining high-quality standards. With the pressure to meet consumer demands swiftly, assembly machines streamline operations by automating repetitive tasks and reducing human error. This not only accelerates the manufacturing process but also frees up skilled workers to focus on more complex operations that require critical thinking and creativity.

Moreover, the integration of advanced technology in assembly machines, such as robotics and artificial intelligence, takes efficiency to the next level. These innovations allow for greater precision and adaptability, enabling manufacturers to swiftly pivot in response to market changes or customized production needs. By investing in the right assembly machine tailored to specific factory requirements, businesses can significantly enhance their productivity, minimize operational costs, and improve overall competitiveness in the manufacturing sector. As factories continue to evolve, understanding and selecting the best assembly machine becomes crucial for sustained success.

Key Considerations for Selecting the Right Assembly Machine for Diverse Factory Needs

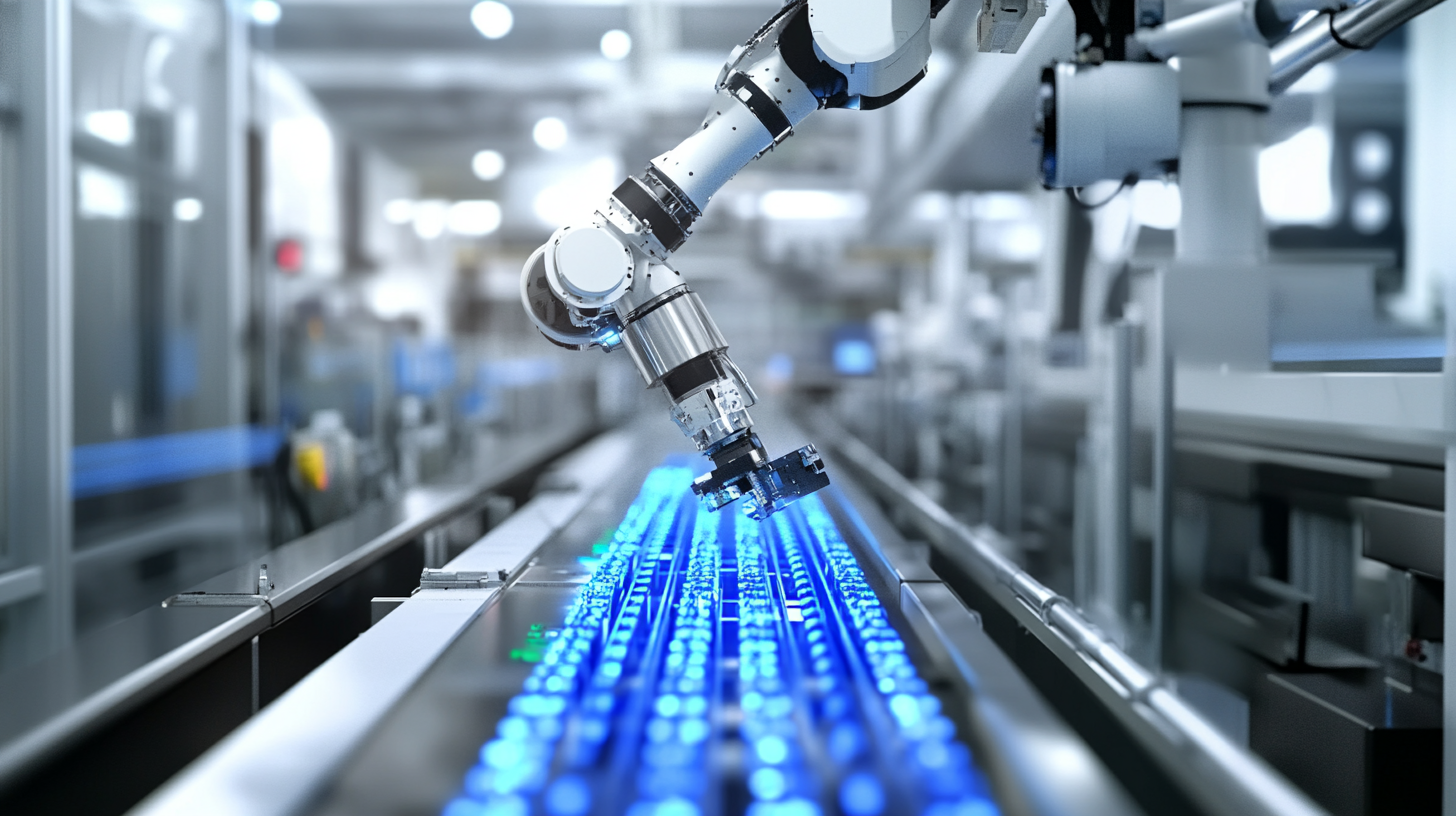

When selecting the right assembly machine for diverse factory needs, several key considerations must be taken into account. The assembly automation landscape is rapidly evolving, driven by the integration of advanced technologies like AI, robotics, and smart manufacturing systems. According to recent reports, investments in industrial automation are projected to grow significantly, with the market expected to reach $210 billion by 2025. This growth underscores the importance of choosing machines that not only meet current production requirements but also integrate seamlessly with future technological advancements.

One major factor to consider is the flexibility of the assembly machines. Six-axis robots, known for their versatility, are increasingly utilized across various industries, particularly in automotive assembly, where they handle a variety of tasks with precision. Additionally, with advancements in AI, predictive maintenance is becoming a standard feature, allowing manufacturers to anticipate and address potential equipment failures before they disrupt production. These innovations not only enhance operational efficiency but also contribute to significant cost savings, making it imperative for factories to invest thoughtfully in their assembly machine choices.

The Definitive Ultimate Guide to Choosing the Best Assembly Machine for Your Factory Needs

| Feature | Description | Importance Level |

|---|---|---|

| Automation Level | Degree to which the machine can operate without human intervention. | High |

| Production Speed | Rate at which the machine can produce assembled products. | High |

| Flexibility | Ability to switch between different product lines with minimal downtime. | Medium |

| Footprint | Amount of floor space the machine occupies in the factory. | Medium |

| Maintenance Requirements | Frequency and complexity of maintenance needed to keep the machine operational. | High |

| Cost | Initial purchase price as well as long-term operational costs. | High |

| User Interface | Ease of use of the machine’s controls and software. | Medium |

Evaluating Technology Trends in Assembly Machines: Automation and Industry 4.0

In today's manufacturing landscape, the integration of automation and artificial intelligence (AI) represents a significant leap towards achieving Industry 4.0 goals.

The rise of the Industrial Internet of Things (IIoT) allows for the interconnection of intelligent devices, enabling real-time monitoring and data exchange that enhance the efficiency of assembly machines. This shift not only optimizes production processes but also ensures that manufacturers can respond swiftly to market demands while minimizing human intervention through robotics and machine learning.

As industries evolve, it is crucial for companies to assess technology trends when selecting assembly machines. The incorporation of synthetic data generation offers innovative solutions to address prevalent challenges, such as data scarcity and privacy concerns in manufacturing. Furthermore, the shift from Industry 4.0 to more advanced stages emphasizes the importance of AI in streamlining supply chain management. By understanding these technology trends, manufacturers can make informed decisions that align with the future of automated production, ensuring they remain competitive in an increasingly digital world.

Cost-Benefit Analysis: Balancing Investment with Production Quality and Speed

Choosing the best assembly machine for your factory is a critical decision that requires a thorough cost-benefit analysis. Understanding the financial implications of your investment is essential to ensure that it aligns with your production goals. When evaluating potential machines, consider not only the upfront costs but also maintenance, operational efficiency, and the potential for future scalability. Investing in a higher-quality machine may incur more significant initial expenses; however, if it leads to enhanced production quality and reduced downtime, the long-term benefits can far outweigh the costs.

Choosing the best assembly machine for your factory is a critical decision that requires a thorough cost-benefit analysis. Understanding the financial implications of your investment is essential to ensure that it aligns with your production goals. When evaluating potential machines, consider not only the upfront costs but also maintenance, operational efficiency, and the potential for future scalability. Investing in a higher-quality machine may incur more significant initial expenses; however, if it leads to enhanced production quality and reduced downtime, the long-term benefits can far outweigh the costs.

Moreover, production quality and speed must be balanced against financial constraints. A high-speed machine might seem enticing, but if it compromises the quality of the final product, it could result in costly reworks or dissatisfied customers. Conversely, a lower-speed machine may enhance quality but could hinder throughput, impacting overall profitability. Therefore, it is vital to assess how each machine's performance metrics align with your factory's specific needs, ensuring that both investment and operational capabilities are optimized for success.

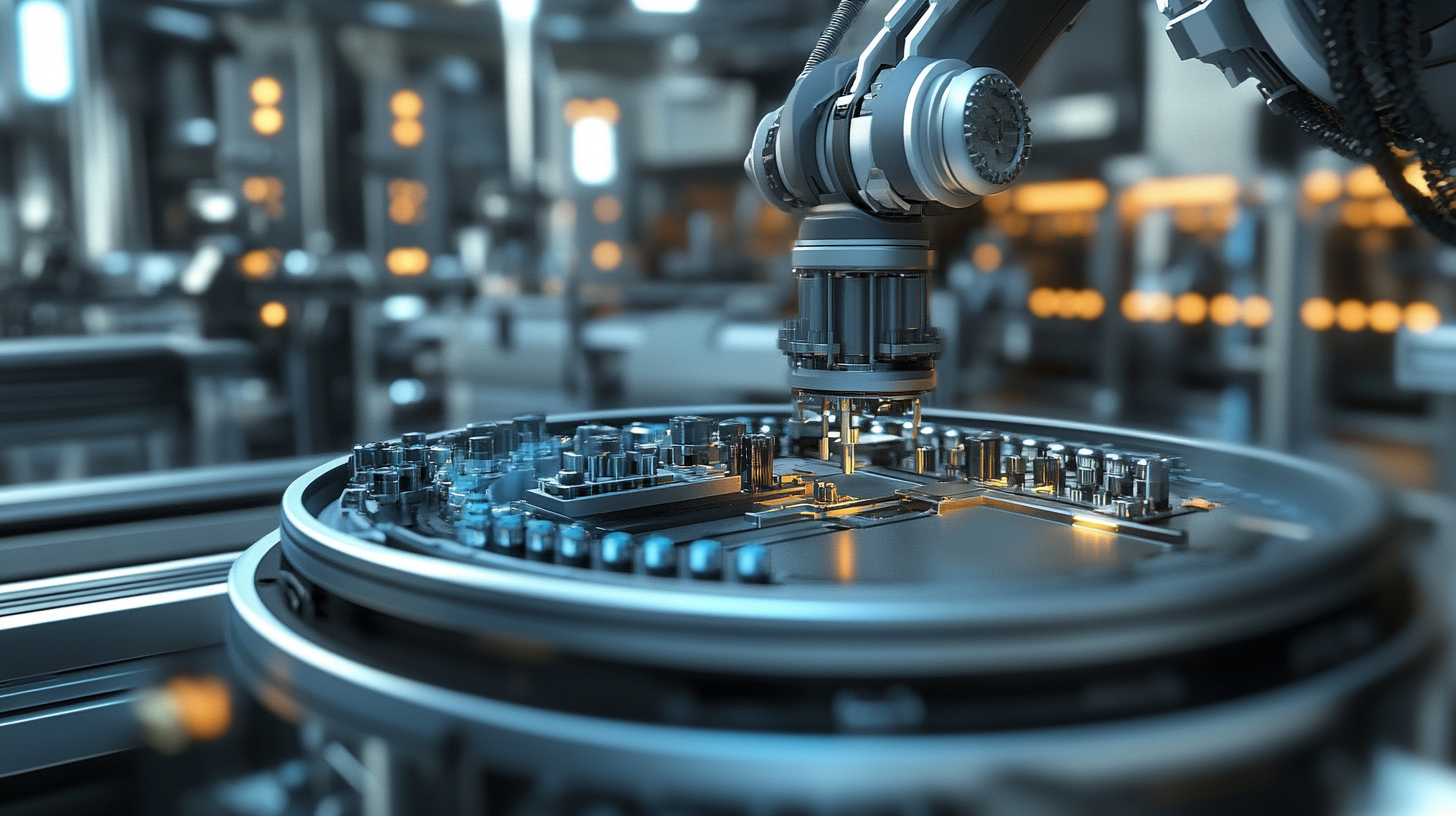

Case Studies: Successful Implementations of Advanced Assembly Machines in China’s Manufacturing Sector

In today’s competitive landscape, the success of manufacturing facilities often hinges on the efficiency and precision of assembly machines. Case studies from China’s manufacturing sector provide compelling evidence of how advanced assembly machines have transformed production processes. Factories that have implemented these machines report increased throughput, improved product quality, and reduced labor costs. For instance, a leading electronics manufacturer in Shenzhen adopted a fully automated assembly line, resulting in a 30% boost in production speed and a significant reduction in errors.

When selecting the best assembly machine for your factory needs, consider the specific requirements of your production line. Tips to keep in mind include evaluating the machine's adaptability to your existing processes, maintenance requirements, and scalability for future growth. It’s also essential to look at machine performance metrics, such as cycle time and efficiency, to ensure you are choosing equipment that delivers optimal results.

Real-life success stories demonstrate the importance of careful machine selection. A textile company in Guangzhou implemented a state-of-the-art assembly machine, which not only streamlined operations but also improved worker safety by reducing manual handling. Such examples highlight the potential for advanced assembly machines to revolutionize production workflows, offering invaluable insights for manufacturers looking to stay ahead in the dynamic market.