Understanding the Importance of Impact Tester in Modern Manufacturing Processes

In modern manufacturing processes, the importance of precision and reliability cannot be overstated, particularly in industries that demand stringent quality control standards. An essential tool in this context is the impact tester, which plays a critical role in assessing the toughness and durability of materials.

According to a recent industry report by MarketsandMarkets, the global impact testing equipment market is projected to reach USD 1.1 billion by 2025, with a compound annual growth rate (CAGR) of 4.6%. This growth underscores the increasing recognition of impact testers as a vital component in ensuring product reliability and safety across various sectors, from automotive to aerospace.

By accurately simulating and measuring the impact forces that materials may encounter in real-world applications, impact testers help manufacturers not only meet regulatory standards but also enhance customer trust and satisfaction.

As industries continue to evolve and face new challenges, the role of impact testers will become increasingly indispensable in meeting the demands of modern manufacturing.

According to a recent industry report by MarketsandMarkets, the global impact testing equipment market is projected to reach USD 1.1 billion by 2025, with a compound annual growth rate (CAGR) of 4.6%. This growth underscores the increasing recognition of impact testers as a vital component in ensuring product reliability and safety across various sectors, from automotive to aerospace.

By accurately simulating and measuring the impact forces that materials may encounter in real-world applications, impact testers help manufacturers not only meet regulatory standards but also enhance customer trust and satisfaction.

As industries continue to evolve and face new challenges, the role of impact testers will become increasingly indispensable in meeting the demands of modern manufacturing.

The Role of Impact Testers in Ensuring Product Quality

In modern manufacturing processes, the significance of impact testers cannot be overstated, particularly in ensuring product quality. Impact testing plays a pivotal role in evaluating the toughness and durability of materials under sudden force, which is essential for industries ranging from aerospace to automotive. According to industry reports, material failures often occur due to insufficient consideration of impact resistance, leading to significant financial losses and safety hazards. With the introduction of advanced impact testing technologies, manufacturers can obtain reliable data that ensures products meet required safety standards.

Recent innovations in quality assurance technology have further bolstered the importance of impact testers in manufacturing. Enhanced testing methods not only improve accuracy but also streamline processes, reducing the time from testing to market. For instance, certified reference materials have been developed to standardize the testing of nanomaterials, providing benchmarks for manufacturers to achieve consistent quality across products. In a landscape where supply chains face increasing challenges, such rigorous testing practices help maintain trust and assure consumers of product safety, ultimately enhancing brand reputation and market success.

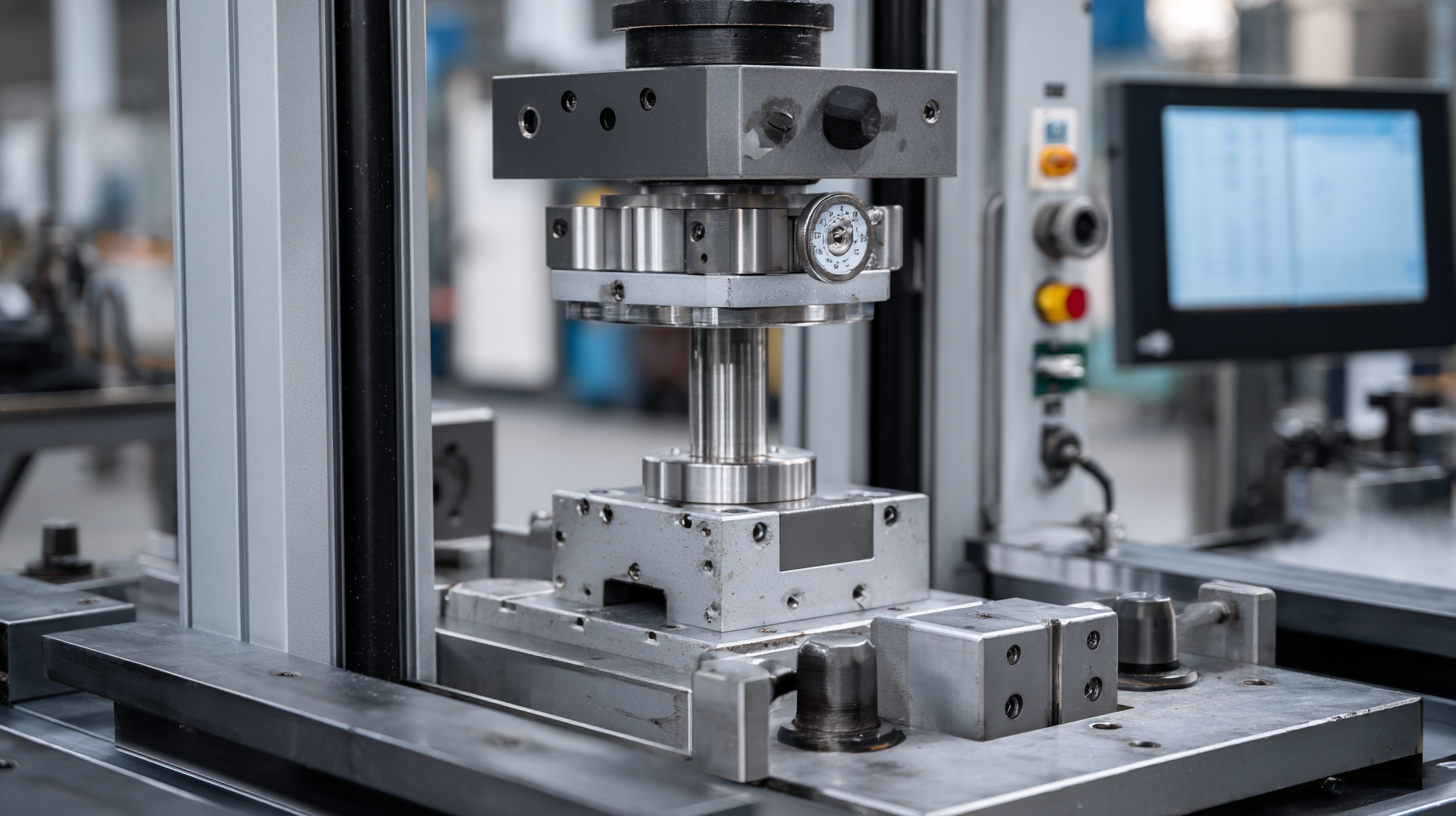

Key Features to Look for in Modern Impact Testing Equipment

When selecting modern impact testing equipment, several key features should be prioritized to ensure the reliability and accuracy of the results. First and foremost, look for a machine that offers adjustable impact energies. This flexibility is crucial for simulating various conditions that materials may encounter in real-world applications. Additionally, an intuitive interface can greatly enhance user experience by allowing operators to easily set parameters and interpret results.

Another important feature is the presence of advanced data acquisition systems. These systems enable real-time monitoring and analysis of the impact test, providing detailed insights into material behavior under different stress conditions. High-resolution cameras and software that assist in visualizing impact events can also be beneficial, offering clearer representation and understanding of the fractures or failures that occur during testing.

**Tip:** Always ensure your impact tester is calibrated and maintained regularly to uphold the accuracy of test outcomes. Inquire about customer support and training programs when purchasing equipment, as knowledgeable assistance can significantly improve your testing processes. Also, consider investing in equipment that has upgradable components, allowing you to adapt to future testing needs easily.

Understanding the Importance of Impact Tester in Modern Manufacturing Processes - Key Features to Look for in Modern Impact Testing Equipment

| Feature | Importance | Specifications | Benefits |

|---|---|---|---|

| Energy Absorption Capacity | Determines the material's ability to withstand impacts without failure. | Up to 100 J | Ensures product durability and reliability. |

| Test Speed | Influences the accuracy of impact results. | Variable up to 5 m/s | Allows for accurate characterization of material behavior. |

| Automatic Control | Reduces human error in testing. | Integrated software system | Enhances test repeatability and reduces operator fatigue. |

| Data Recording and Analysis | Facilitates detailed evaluation of impact results. | Real-time data logging | Provides comprehensive insights for quality control. |

| Compact Design | Enables usage in limited laboratory spaces. | Dimensions: 30" x 20" x 20" | Ideal for diverse manufacturing environments. |

How Impact Testing Contributes to Safety in Manufacturing

Impact testing plays a crucial role in enhancing safety standards across various manufacturing sectors, particularly in automotive and child safety equipment. Recent regulations by the National Highway Traffic Safety Administration (NHTSA) highlight the necessity of side-impact testing for car seats, aimed at better protecting children during potential accidents. Car seats sold in the U.S. must now satisfy these enhanced safety standards, transitioning to include rigorous sled tests that simulate high-speed collisions. This shift illustrates how impact testing directly influences manufacturing practices to safeguard users.

Tips: When selecting a child car seat, ensure that it meets the latest federal safety standards, including side-impact testing. Regularly check that your current car seat complies with the upcoming regulations, and consult consumer reports for detailed performance results. Additionally, consider products with proven track records in safety testing to maximize protection for your young passengers.

Best Practices for Implementing Impact Testing in Production Lines

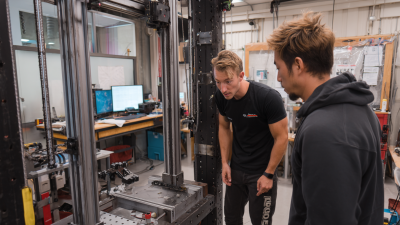

Implementing impact testing in production lines is crucial for ensuring product durability and reliability. To begin with, manufacturers should conduct a thorough assessment of the material types used in their products. Understanding the intrinsic properties of these materials allows manufacturers to select the appropriate impact testing methods. Utilizing standardized tests, such as Charpy or Izod, can help in benchmarking material performance against industry standards, ensuring the components can withstand potential impacts during usage.

Training staff on the importance of impact testing is another best practice. This involves not only educating them about the testing procedures but also emphasizing the significance of accurate results in maintaining product quality and safety. Moreover, incorporating regular maintenance schedules for impact testing equipment is essential. Regular calibration and inspection keep machines in optimal condition, reducing variability in test results and enhancing the reliability of quality assurance processes.

By prioritizing these practices, manufacturers can effectively integrate impact testing into their production lines, leading to improved product longevity and customer satisfaction.

Case Studies: Successful Impact Testing Applications in Various Industries

In today's manufacturing landscape, the role of impact testers has become crucial across various industries. Case studies illustrate their successful application, particularly in sectors like automotive, aerospace, and construction. For instance, the automotive industry employs impact testing to ensure vehicle components can withstand sudden forces, enhancing safety and reliability.

Similarly, aerospace manufacturers utilize these tests to guarantee that materials can endure extreme conditions during flight, thereby minimizing risks associated with structural failure.

Similarly, aerospace manufacturers utilize these tests to guarantee that materials can endure extreme conditions during flight, thereby minimizing risks associated with structural failure.

Tips for effectively implementing impact testing include investing in advanced testing equipment that can provide precise measurements and insights. Regularly training staff on the importance of impact testing and how to interpret results can lead to better application of the findings. Moreover, collaborating with material scientists can help in optimizing materials specifically designed for high-impact resistance, ensuring that products meet industry standards and customer expectations.

By prioritizing these practices, manufacturers can significantly improve their product quality and performance, giving them a competitive edge in the market.

Related Posts

-

The Future of Impact Testing Technology: Innovations Shaping Enhanced Durability Standards

-

How to Choose the Right Resistance Tester for Your Electrical Applications

-

The Ultimate Guide to Choosing the Best Phone Testing Equipment for Your Needs

-

How to Optimize Your Testing Rigs for Enhanced Performance and Accuracy

-

Revolutionizing Quality Control: The Impact of Testing Meters in Modern Manufacturing Industries

-

The Ultimate Guide to Choosing the Best Quality Testing Equipment for Your Business