Exploring Innovative Alternatives to the Best Automatic Assembly Machine for Global Buyers

In the rapidly evolving landscape of manufacturing, the demand for efficient and reliable production solutions has never been higher. According to a recent report by MarketsandMarkets, the global market for automatic assembly machines is projected to reach $7.8 billion by 2025, growing at a CAGR of 6.2%. This surge reflects the increasing need for automation across various sectors, particularly in electronics, automotive, and consumer goods. As global buyers seek the best automatic assembly machines to enhance productivity and reduce labor costs, it is crucial to explore innovative alternatives that not only meet these demands but also offer improved flexibility and adaptability to changing production requirements. This blog will delve into the latest advancements and creative solutions in automatic assembly technologies, showcasing examples that illustrate how manufacturers can optimize their operations while remaining competitive in a dynamic marketplace.

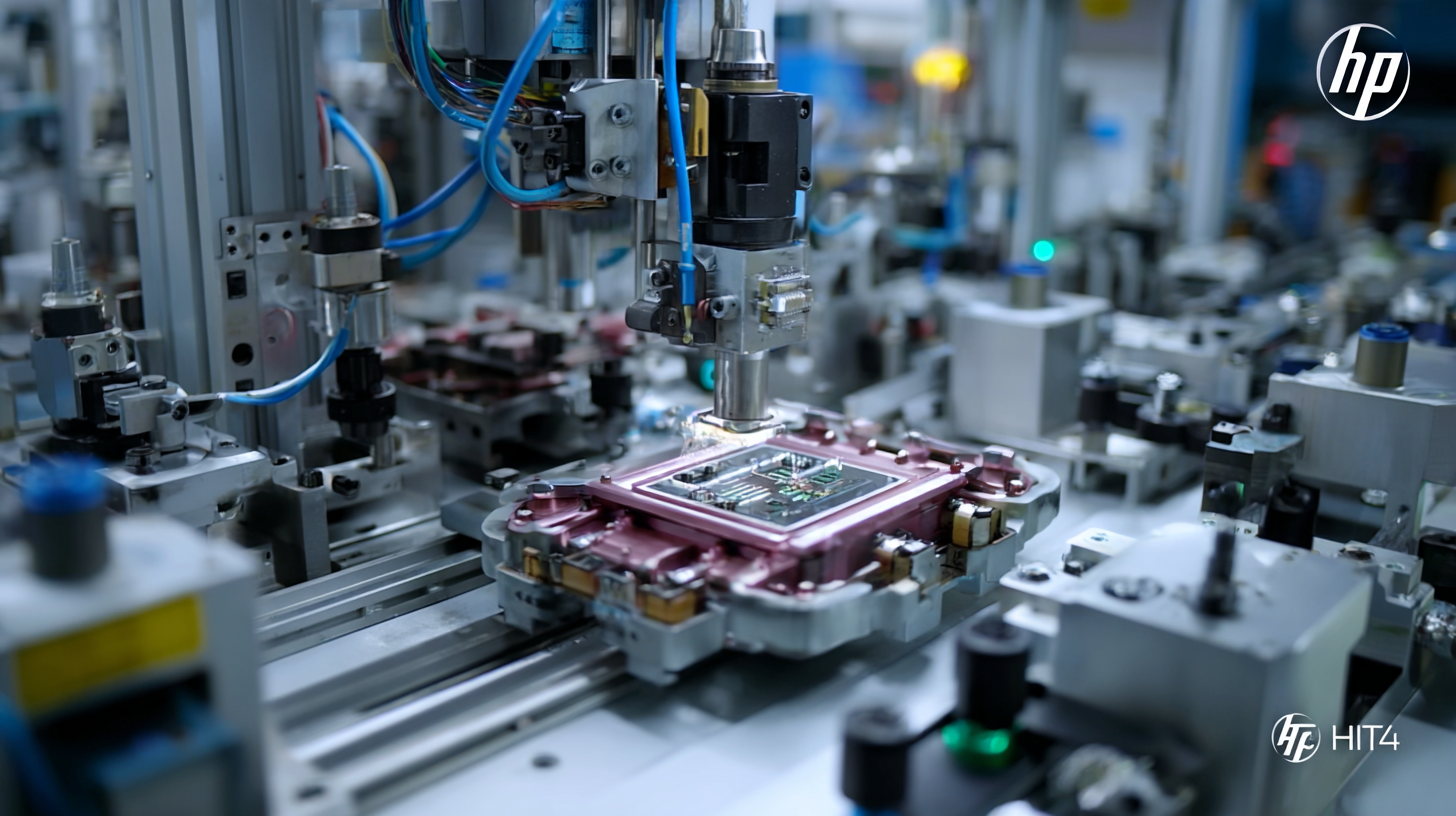

Innovative Automatic Assembly Machines: A Game Changer for Global Industries

The rise of innovative automatic assembly machines is revolutionizing global industries, significantly enhancing efficiency and reducing production costs. According to a recent report by MarketsandMarkets, the automatic assembly machine market is projected to grow from USD 18.6 billion in 2023 to USD 29.6 billion by 2028, at a CAGR of 9.4%. This surge reflects a widespread industry shift towards automation, driven by the need for increased productivity and quality control.

These machines not only streamline the assembly process but also incorporate advanced technologies such as artificial intelligence and machine learning. A study by ResearchAndMarkets highlighted that AI-driven assembly machines can reduce operational costs by up to 20%, while increasing throughput. Consequently, industries ranging from automotive to electronics are rapidly adopting these innovations to stay competitive. As manufacturers explore alternatives to traditional assembly solutions, the integration of automated systems stands as a key differentiator in achieving operational excellence and meeting stringent market demands.

Comparative Analysis of Traditional vs. Innovative Assembly Solutions

In the rapidly evolving manufacturing landscape, the debate between traditional and innovative automatic assembly solutions has become increasingly relevant. Traditional assembly machines, while dependable, often come with high capital costs and limited flexibility. According to a report by Technavio, the global automatic assembly equipment market is expected to grow by USD 2.57 billion from 2021 to 2025, driven in part by the need for more versatile production lines. Traditional machines typically struggle to adapt to varied product lines without significant downtime, making them less suitable for modern demands where customization and speed are essential.

Conversely, innovative assembly solutions, such as collaborative robots (cobots) and flexible automation systems, are redefining efficiency in assembly processes. A study by MarketsandMarkets projects that the cobot market will reach USD 12.3 billion by 2025, reflecting an annual growth rate of over 40%. These innovative alternatives not only increase productivity but also enhance safety and reduce labor costs by working alongside human operators. By utilizing advanced technologies, such as AI and machine learning, companies can achieve greater precision and flexibility, positioning themselves competitively in the global marketplace. Such advancements signal a transformative shift in assembly approaches that can significantly influence operational excellence.

The Economic Impact of Adopting Advanced Assembly Technologies

The adoption of advanced assembly technologies is poised to have a profound impact on the global economy, particularly in the context of manufacturing. As industries transition into the era of Industry 4.0, characterized by enhanced connectivity and automation, the economic landscape will inevitably shift. Economists project that by embracing these innovative technologies, the U.S. manufacturing sector can not only bolster productivity but also create substantial revenue streams, projected to reach anywhere from $300 to $400 billion by 2035 in adjacent fields like autonomous driving.

Moreover, the economic implications extend beyond mere profitability. The integration of advanced assembly machines fosters a more skilled workforce, potentially alleviating poverty through higher-paying job opportunities. While concerns about declining manufacturing jobs persist, the movement towards automation signifies a transformation rather than a retrenchment; it encourages a shift from manual labor to skilled technical roles, thereby enriching the overall labor market. As companies invest in advanced manufacturing facilities, they are not just enhancing efficiency but also contributing to regional economic hubs, reinforcing the importance of technological advancement in driving sustainable growth.

Sustainability and Efficiency: Benefits of Modern Assembly Machines

Modern assembly machines are revolutionizing the manufacturing landscape, providing sustainable and efficient alternatives to traditional methods. These innovative technologies not only enhance productivity but also minimize waste and energy consumption, offering significant benefits for global buyers looking to adopt greener practices. By integrating automation and smart technologies, manufacturers can streamline operations, reduce downtime, and improve overall product quality.

When considering a modern assembly machine, sustainability should be a key factor. Look for machines that utilize energy-efficient components and eco-friendly materials, which can lead to reduced operational costs over time. Additionally, prioritize machines that offer versatility, allowing for quick adjustments to accommodate different product lines or manufacturing processes.

To maximize efficiency, invest in training programs for your staff to ensure they are well-versed in the latest technologies. Proper training can help minimize errors in operation, further enhancing productivity and reducing waste. Furthermore, consider implementing real-time monitoring systems that provide insights into machine performance, enabling timely maintenance and reducing the risk of costly downtimes. By focusing on these aspects, companies can truly harness the benefits of modern assembly machines.

Exploring Innovative Alternatives to the Best Automatic Assembly Machine for Global Buyers - Sustainability and Efficiency: Benefits of Modern Assembly Machines

| Feature | Description | Sustainability Impact | Efficiency Rating |

|---|---|---|---|

| Energy Efficiency | Utilizes advanced energy-saving technologies | Reduces energy consumption by up to 30% | High |

| Material Waste Reduction | Optimized processes minimize scrap and waste | Decreases material waste by 20% | Very High |

| Modular Design | Allows for easy upgrades and customization | Promotes longer equipment lifespan | Moderate |

| Integration with AI | Incorporates smart technology for improved decision-making | Enhances operational sustainability | Very High |

| User-Friendly Interface | Simple and intuitive controls for operators | Reduces training time and operational errors | High |

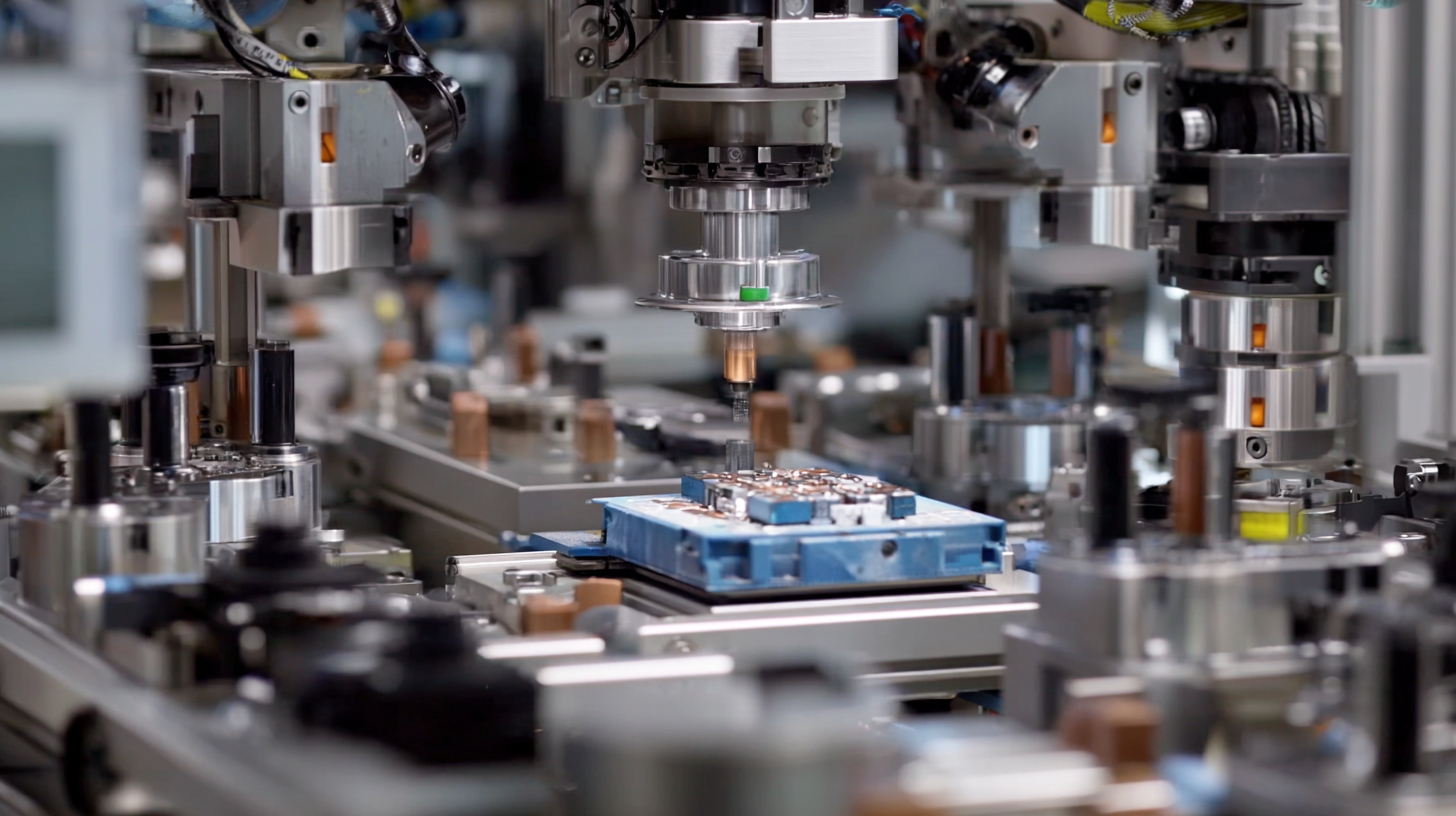

Case Studies: Successful Implementations of Innovative Assembly Systems

In recent years, the manufacturing industry has witnessed a surge in innovative assembly systems that offer efficient alternatives to traditional automatic assembly machines. Companies across the globe are exploring these cutting-edge technologies to enhance production capabilities and reduce costs. Several case studies highlight the successful implementation of these systems, showcasing their potential to streamline operations. For instance, a leading electronics manufacturer adopted a collaborative robotic assembly system, leading to a 30% reduction in assembly time and a significant improvement in product consistency.

Another compelling case involves a car manufacturer that integrated a flexible assembly line using modular robotics. This approach allowed them to quickly adapt to changing market demands and reduce downtime. By leveraging advanced automation technologies such as AI-driven quality control and predictive maintenance, the company not only improved efficiency but also maintained high standards of product quality. Such implementations inspire other global buyers to rethink their assembly strategies, leading to a more innovative and responsive manufacturing landscape.