Innovative Solutions to Common Challenges in Food Packaging with Best Assembly Machine

In the ever-evolving food packaging industry, businesses face a myriad of common challenges that require innovative solutions to stay competitive. The global food packaging market is projected to reach $600 billion by 2025, reflecting an increasing demand for efficient and sustainable packaging methods. One of the pivotal technologies driving this change is the Assembly Machine, which significantly enhances production efficiency while minimizing waste. According to a recent report by Smithers Pira, advancements in packaging machinery, including automated assembly solutions, can lead to a reduction in labor costs by up to 30% and improve overall throughput by 25%. As companies strive to address sustainability concerns and meet consumer expectations for convenience and safety, the integration of advanced assembly machines into their operations becomes a crucial step in overcoming these challenges and optimizing packaging processes.

In the ever-evolving food packaging industry, businesses face a myriad of common challenges that require innovative solutions to stay competitive. The global food packaging market is projected to reach $600 billion by 2025, reflecting an increasing demand for efficient and sustainable packaging methods. One of the pivotal technologies driving this change is the Assembly Machine, which significantly enhances production efficiency while minimizing waste. According to a recent report by Smithers Pira, advancements in packaging machinery, including automated assembly solutions, can lead to a reduction in labor costs by up to 30% and improve overall throughput by 25%. As companies strive to address sustainability concerns and meet consumer expectations for convenience and safety, the integration of advanced assembly machines into their operations becomes a crucial step in overcoming these challenges and optimizing packaging processes.

Understanding Common Challenges in Food Packaging

In the realm of food packaging, understanding common challenges is essential for developing innovative solutions. One significant issue is the environmental impact of plastic waste, which is a pressing concern as billions of tons of plastic end up in landfills and oceans every year. According to a report by the World Economic Forum, if current trends continue, the amount of plastic in the ocean could outweigh all the fish by 2025. This highlights the urgent need for the food industry to explore sustainable alternatives that can alleviate the reliance on single-use plastics.

Additionally, the push for sustainable palm oil production presents another challenge in food packaging. With palm oil being one of the most widely used vegetable oils globally, ensuring its sourcing does not contribute to deforestation or loss of biodiversity is crucial. The Roundtable on Sustainable Palm Oil (RSPO) emphasizes that nearly 60% of palm oil produced is still not certified as sustainable. By incorporating sustainable practices and utilizing intelligent design technology, the food packaging industry can address these challenges while minimizing environmental footprints. Innovative approaches, such as AI-generated packaging designs, have the potential to revolutionize the industry, making packaging not only functional but also eco-friendly, thereby resonating with the growing consumer demand for responsible sourcing.

Exploring Innovative Assembly Machines for Food Packaging Solutions

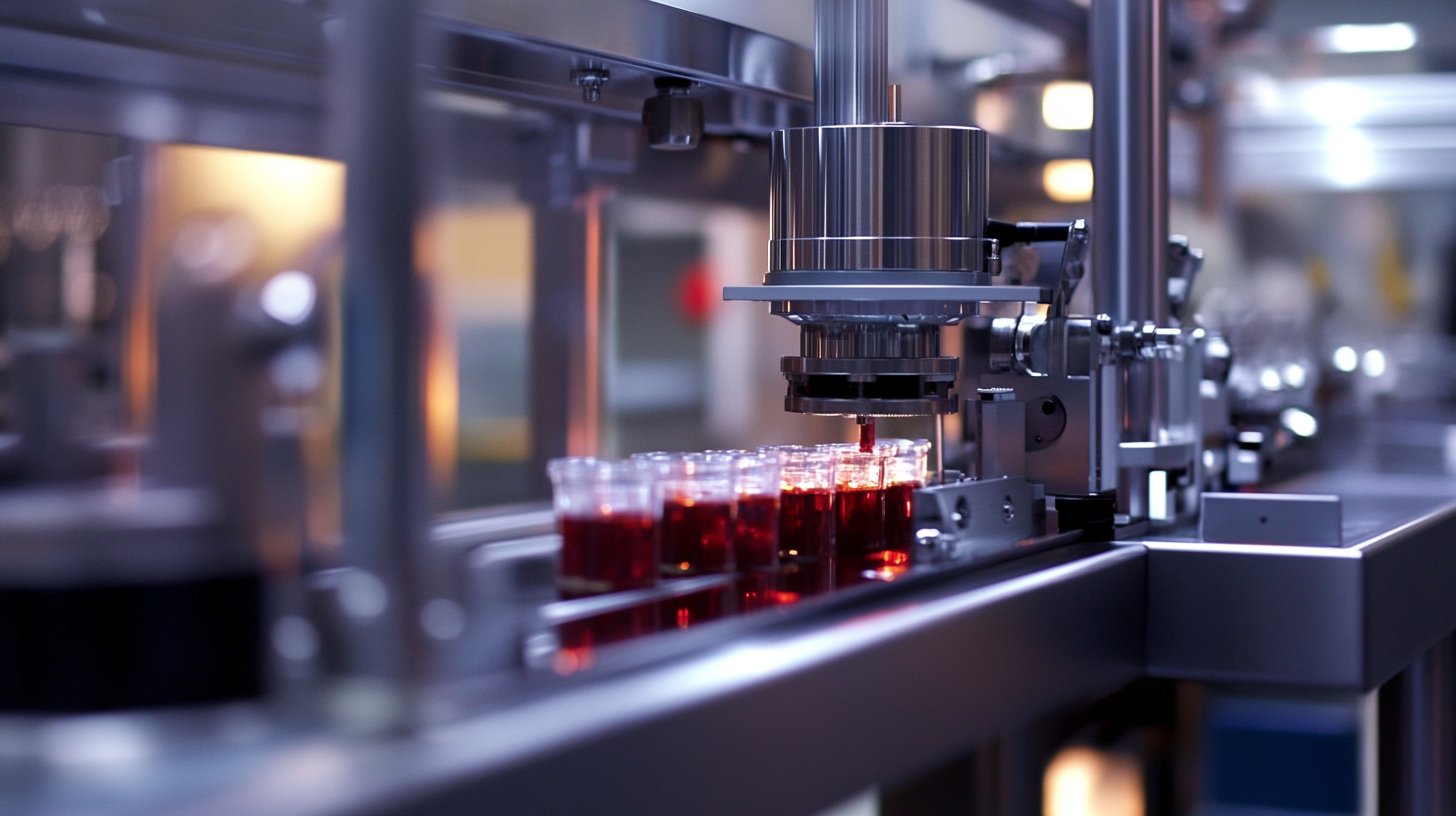

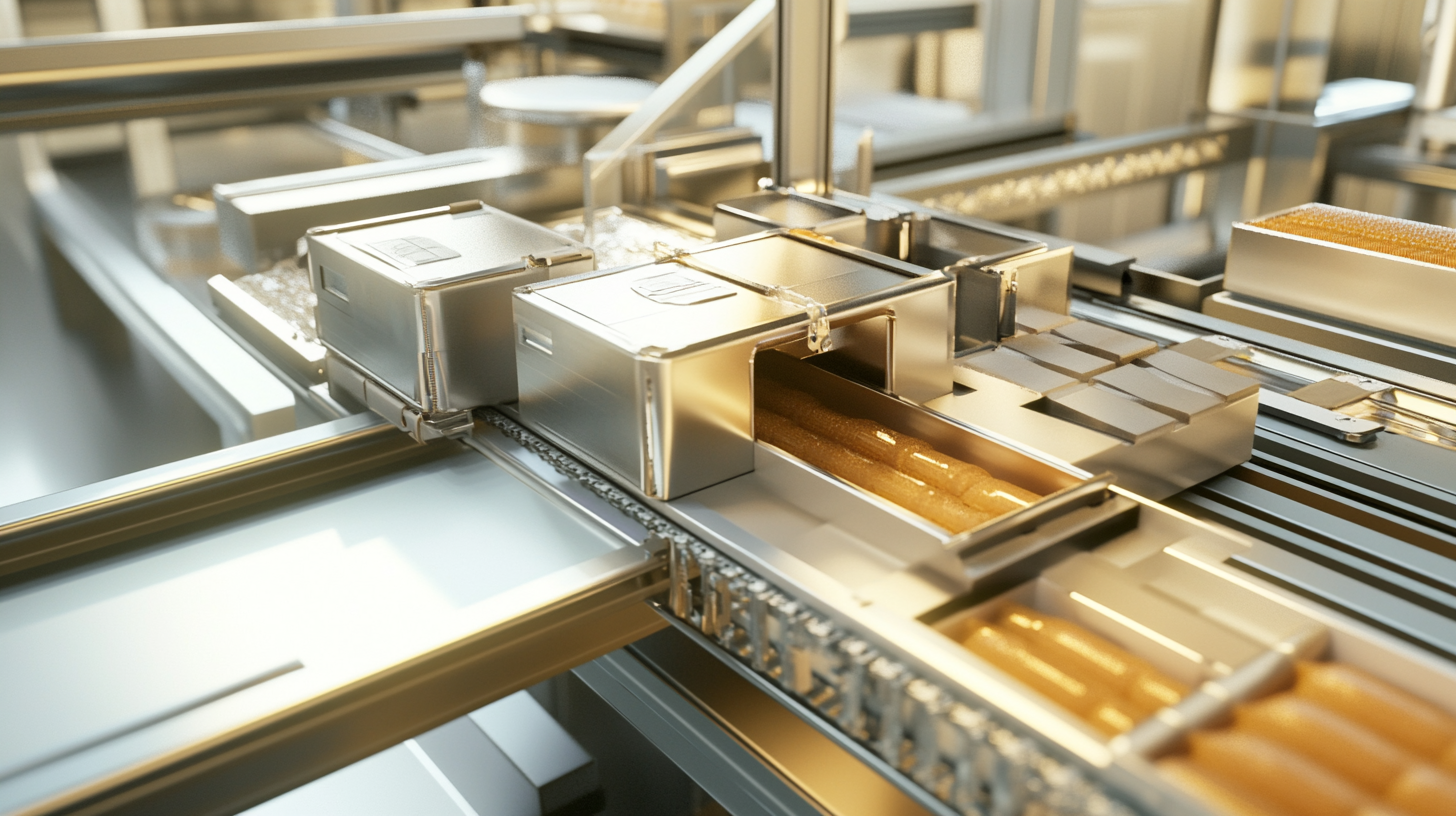

The world of food packaging is evolving rapidly, driven by the need for efficiency, sustainability, and hygiene. Innovative assembly machines are at the forefront of this transformation, providing solutions that address common challenges faced by food manufacturers. These machines not only streamline production processes but also ensure that products are packaged in a way that extends shelf life and preserves quality. By integrating advanced technologies such as robotics and automation, businesses can enhance their packaging lines and optimize overall productivity.

Tip: When evaluating assembly machines for food packaging, consider machines that offer flexibility in size and shape adjustments. This adaptability can save time and reduce waste, allowing companies to run multiple product lines with ease.

Tip: Assess the energy efficiency of assembly machines, as reducing energy consumption can lead to significant cost savings over time while contributing to environmental goals.

Sustainable Materials: Reducing Waste in Food Packaging

Sustainable materials are becoming increasingly vital in the food packaging industry as brands strive to reduce environmental impacts. According to a report by Smithers Pira, the global market for sustainable packaging is projected to reach $500 billion by 2024, driven by rising consumer demand for eco-friendly packaging. This shift is not only about attracting environmentally conscious consumers but also about complying with stricter regulations on waste management and recycling.

One innovative solution gaining traction is the use of biodegradable and compostable materials. These materials break down more easily in landfills or composting facilities, significantly reducing the waste footprint associated with traditional packaging. For instance, a recent survey indicated that over 70% of consumers are willing to pay more for sustainable packaging options, which compels manufacturers to adopt these alternatives. Additionally, companies that incorporate sustainable practices into their packaging strategies typically experience increased brand loyalty and positive consumer perceptions, highlighting the economic benefits of embracing sustainability.

Furthermore, advancements in assembly machine technology are enabling producers to implement these sustainable materials more efficiently. Machines designed with precision can handle a variety of biodegradable substrates without compromising speed or quality, ensuring that companies can meet growing demand without sacrificing performance. As the food packaging landscape continues to evolve, it is clear that prioritizing sustainable materials will play a crucial role in shaping a more environmentally responsible industry.

Maximizing Efficiency: Automation in Food Packaging Processes

In the fast-evolving food industry, automation has become crucial for maximizing efficiency in packaging processes. With the rise of innovative solutions, assembly machines are playing a pivotal role in streamlining operations. Embracing automation not only enhances output but also minimizes human error, ensuring product integrity and safety.

Tips for integrating automation into your food packaging workflow include investing in high-quality assembly machines that offer flexibility for various product types. Additionally, ensure that your machinery can be easily integrated with existing processes. Regular maintenance and updates to your systems are also essential to keep up with the rapid advancements in technology.

Another key aspect is employee training. As automation takes center stage, workers should be equipped with the necessary skills to operate and troubleshoot machinery efficiently. Offering continuous education on new technologies will empower your team and drive productivity, enabling your operation to adapt quickly in a dynamic industry.

Innovative Solutions to Common Challenges in Food Packaging

Case Studies: Successful Implementation of Advanced Packaging Solutions

In recent advancements within the food packaging industry, innovative solutions are addressing common challenges faced by producers. The integration of advanced assembly machines has proven pivotal in enhancing efficiency and sustainability. For example, case studies reveal that companies adopting state-of-the-art packaging techniques not only streamline production processes but also respond more effectively to environmental concerns.

One notable trend is the increasing emphasis on sustainability, evidenced by the recent publication of a comprehensive report on glass packaging recycling in the food and beverage sector. This document highlights successful implementations and serves as a benchmark for industry practices. By adopting measures that focus on the circular economy, companies can significantly reduce their environmental impact while maintaining product integrity.

Tips: When choosing packaging solutions, consider the environmental footprint of materials used, as sustainable options can enhance brand reputation. Additionally, leveraging AI technologies can provide deeper customer insights, allowing businesses to tailor their products and packaging to better meet consumer needs. Investing in advanced machinery not only improves efficiency but also positions your brand as a leader in innovation.