How to Optimize Your Testing Rigs for Enhanced Performance and Accuracy

In the quest for superior performance and accuracy in various engineering applications, optimizing testing rigs is paramount. A recent study by the International Testing Standards Association highlighted that improperly calibrated testing rigs can introduce errors of up to 15%, significantly affecting the reliability of results across multiple sectors, including aerospace and automotive engineering. As industries strive to meet increasingly stringent quality control measures, the focus on enhancing testing rigs has never been more critical.

Advanced methodologies such as automation, real-time data analysis, and sophisticated calibration techniques are transforming the landscape of testing rig performance. By leveraging these innovations, organizations can ensure that their testing rigs not only meet regulatory standards but also provide accurate and consistent data crucial for decision-making and product development. The evolution of testing rigs is essential for maintaining competitiveness in a rapidly advancing technological environment.

Understanding the Importance of Optimizing Testing Rigs for Performance

Optimizing testing rigs is crucial for achieving superior performance and accuracy. In any testing environment, the rigs serve as the foundation for reliable results. When properly optimized, these rigs can dramatically reduce variability, leading to more precise measurements and data collection. This optimization allows engineers and researchers to identify issues quickly and implement solutions more effectively, ultimately speeding up the development process.

One of the key aspects of enhancing testing rig performance is the calibration of instruments and equipment. Regular maintenance and upgrades ensure that all components operate at peak efficiency. Moreover, software configurations can play a significant role; utilizing advanced data analysis tools allows teams to interpret results with greater clarity. By understanding the intricate relationship between testing equipment and the data generated, organizations can make well-informed decisions that enhance both their products and processes.

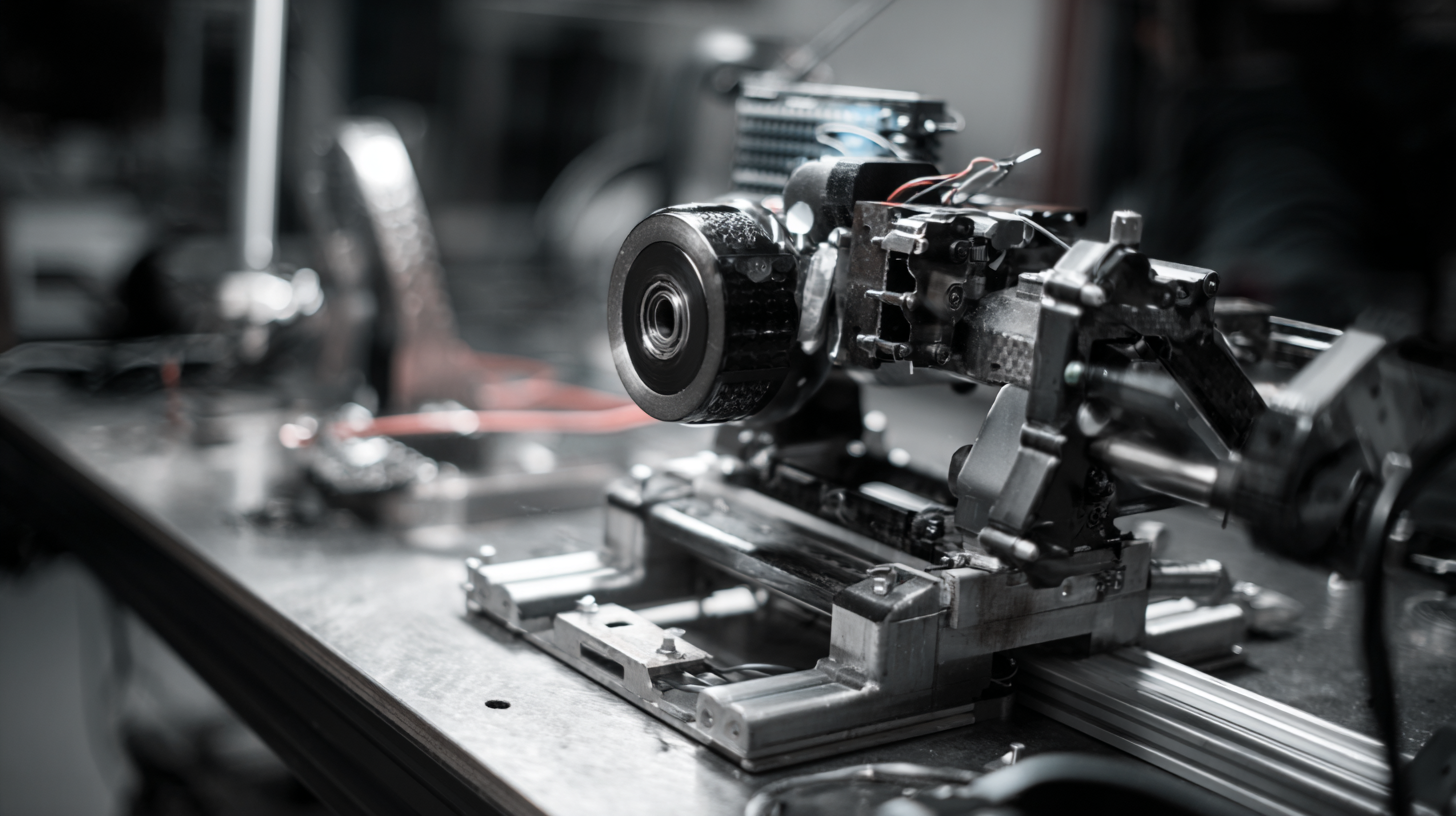

Identifying Key Factors Affecting Performance and Accuracy in Testing Rigs

When it comes to optimizing testing rigs for enhanced performance and accuracy, several key factors play a critical role. Firstly, the calibration of equipment is paramount. Accurate calibration ensures that measurements taken are reliable and reflect true values. Regularly checking and adjusting specific parameters can prevent discrepancies in test results, ultimately improving the overall accuracy of the testing process.

Secondly, the environment in which testing rigs operate significantly impacts their performance. Factors such as temperature, humidity, and vibration can introduce variables that skew results. Maintaining a controlled and stable environment helps minimize these external influences, ensuring that the data collected during testing is both consistent and trustworthy. Additionally, using high-quality materials and components in the construction of testing rigs can further enhance performance, providing durability and precision that are essential for precise measurements.

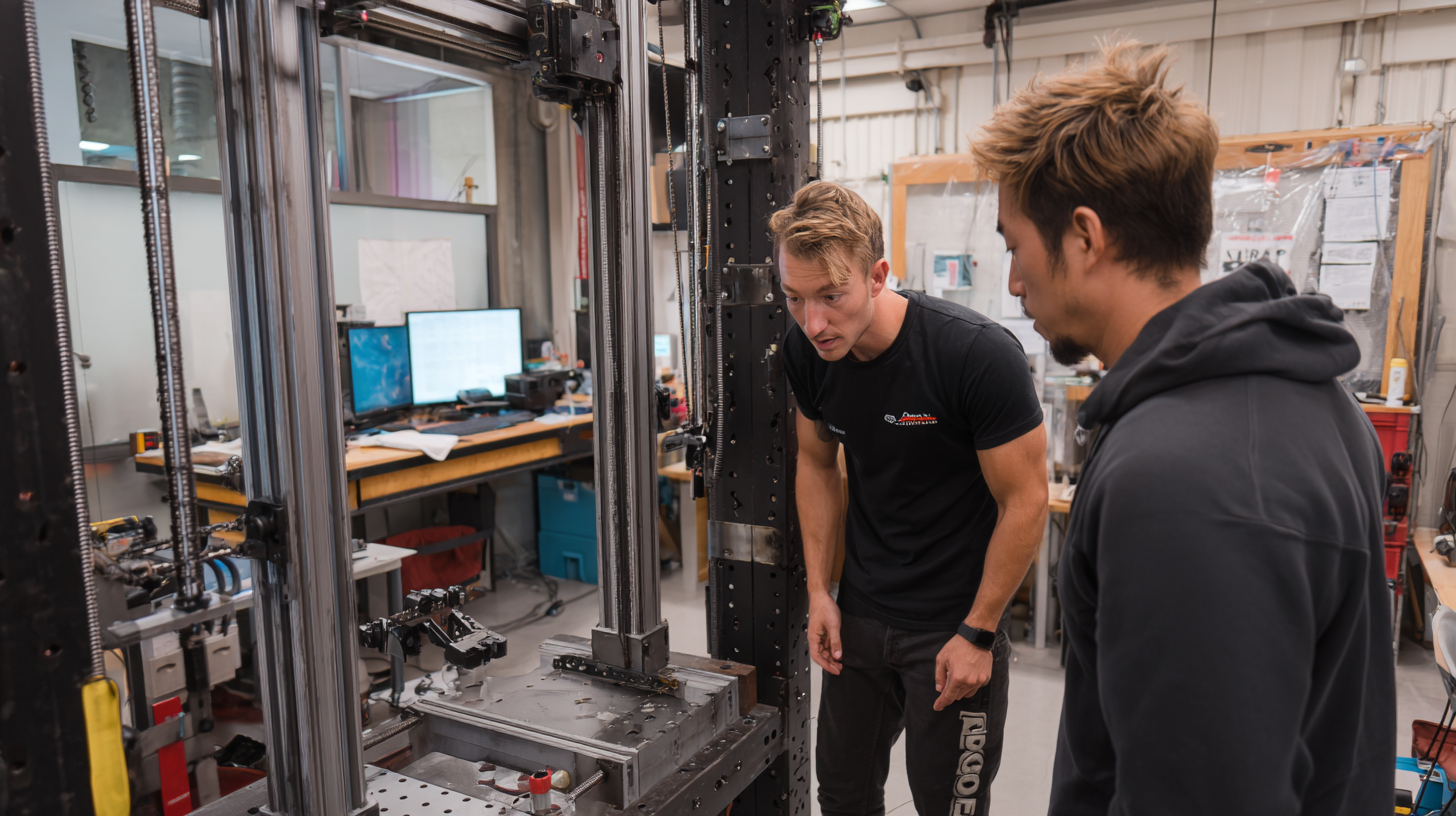

Implementing Hardware Upgrades for Enhanced Testing Rig Efficiency

Upgrading hardware components is essential for maximizing the efficiency of your testing rigs. By investing in higher-spec CPUs and more RAM, you can significantly enhance the processing speed and multitasking capabilities of your testing environment. A powerful CPU can handle complex computations more effectively, while increased RAM allows for running multiple simulations or tests simultaneously without a drop in performance. Additionally, incorporating solid-state drives (SSDs) can drastically reduce data retrieval times, enabling faster loading of applications and results.

Another crucial aspect of hardware upgrades is ensuring that your testing rig has the appropriate power supply and cooling solutions. A reliable power supply can stabilize the components, reducing the risk of failures during extensive testing sessions. Moreover, efficient cooling systems prevent overheating, which can lead to throttling and compromised accuracy. By focusing on these hardware enhancements, you can create a robust testing environment that not only improves performance but also ensures the reliability of your test results.

Testing Rig Performance Optimization

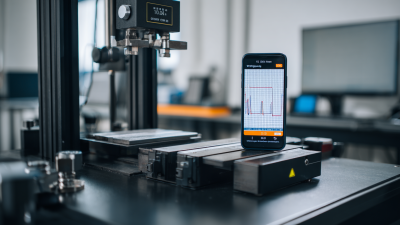

Leveraging Software Solutions to Improve Testing Precision and Speed

To enhance the accuracy and speed of your testing rigs, leveraging advanced software solutions is essential. Modern testing frameworks incorporate automated processes that not only streamline workflows but also minimize human error, resulting in more reliable outcomes. By utilizing software that integrates data analytics, testers can quickly identify patterns and anomalies, allowing for timely adjustments to testing parameters.

Tip 1: Invest in automation tools that fit your specific testing needs. Automation not only increases the speed of tests but also helps in replicating test conditions consistently, which is vital for achieving accurate results.

Moreover, consider employing cloud-based testing solutions. These platforms provide scalable resources and facilitate real-time collaboration among team members, regardless of their geographical locations. This approach not only boosts efficiency but also enhances the precision of testing through immediate feedback loops.

Tip 2: Utilize version control software for your testing scripts. This practice ensures that changes and updates are tracked effectively, helping to maintain consistency and accuracy across multiple test iterations.

Incorporating these software solutions into your testing rigs optimizes performance, allowing you to achieve greater precision and speed in your results.

Establishing Regular Maintenance Practices for Longevity and Reliability in Testing Rigs

Establishing regular maintenance practices for testing rigs is crucial for ensuring longevity and reliability. According to a report by the National Institute of Standards and Technology (NIST), regularly maintained equipment can reduce downtime by up to 30%, significantly improving overall productivity. This highlights the importance of setting a schedule for routine checks, calibrations, and cleaning. By implementing a disciplined approach to maintenance, organizations can avoid the pitfalls of equipment failure, which can lead to costly delays and inaccurate results.

Moreover, industry research from the Equipment Reliability Institute (ERI) indicates that companies that invest in preventive maintenance see a 20% increase in operational efficiency. Performing systematic inspections and promptly addressing any irregularities not only extends the lifespan of testing rigs but also ensures that they deliver consistent and accurate data. For instance, maintaining proper calibration can prevent a deviation of up to 5% in critical measurements, essential in high-stakes environments such as aerospace testing or pharmaceutical quality assurance. By prioritizing maintenance, organizations not only safeguard their investment but also enhance the integrity of their testing outcomes.

Related Posts

-

The Ultimate Guide to Choosing the Best Phone Testing Equipment for Your Needs

-

How to Optimize Your Phone Testing Equipment for Accurate Performance Metrics

-

Innovative Solutions for Precision Line Testers

-

The Ultimate Guide to Choosing the Best Quality Testing Equipment for Your Business

-

The Future of Impact Testing Technology: Innovations Shaping Enhanced Durability Standards

-

Maximizing Efficiency with Field Test Equipment Advantages for Your Business