What is Pile Testing Equipment and How Does it Ensure Structural Integrity

Pile testing equipment plays a crucial role in ensuring the structural integrity of buildings and infrastructure projects. As foundations are the backbone of any construction, the reliability of pile foundations is paramount to the safety and longevity of a structure. This equipment is designed to assess the load-bearing capacity and integrity of piles, which are essential components that support heavy loads. By evaluating the performance of these piles under various conditions, engineers can make informed decisions regarding design and construction, ultimately preventing costly failures and ensuring public safety.

Through a variety of testing methods, pile testing equipment facilitates a comprehensive understanding of how piles behave in response to applied loads, soil conditions, and environmental factors. From static load tests to dynamic testing techniques, these tools provide critical data that aid in verifying that piles are installed correctly and functioning as intended. With advances in technology, modern pile testing equipment has become increasingly sophisticated, making it easier for engineers to perform accurate assessments and bolster the reliability of foundation systems. Consequently, this not only enhances the overall safety of constructions but also supports the sustainable development of infrastructure projects.

Understanding Pile Testing Equipment: Definition and Purpose

Pile testing equipment plays a crucial role in assessing the integrity of pile foundations, which are integral to the stability of various structures. At its core, this equipment is designed to evaluate the load-bearing capacity and structural behavior of piles before and during construction. It serves multiple purposes, including verifying design assumptions, ensuring compliance with safety standards, and identifying potential flaws in pile installation. By using methods such as static load testing, dynamic load testing, and integrity testing, engineers can gather vital information about the performance of piles, ultimately safeguarding against structural failure.

Understanding the purpose of pile testing equipment goes beyond mere compliance; it is about securing the longevity and safety of infrastructures. The data obtained from these tests informs engineers regarding soil conditions, pile material integrity, and the overall effectiveness of the foundation design. This knowledge enables them to make informed decisions, fostering confidence in the structural framework that supports buildings, bridges, and other critical constructions. By identifying challenges before they impact the project, pile testing equipment ensures that structures are built on solid ground, both literally and figuratively.

Types of Pile Testing Methods Used in Structural Assessments

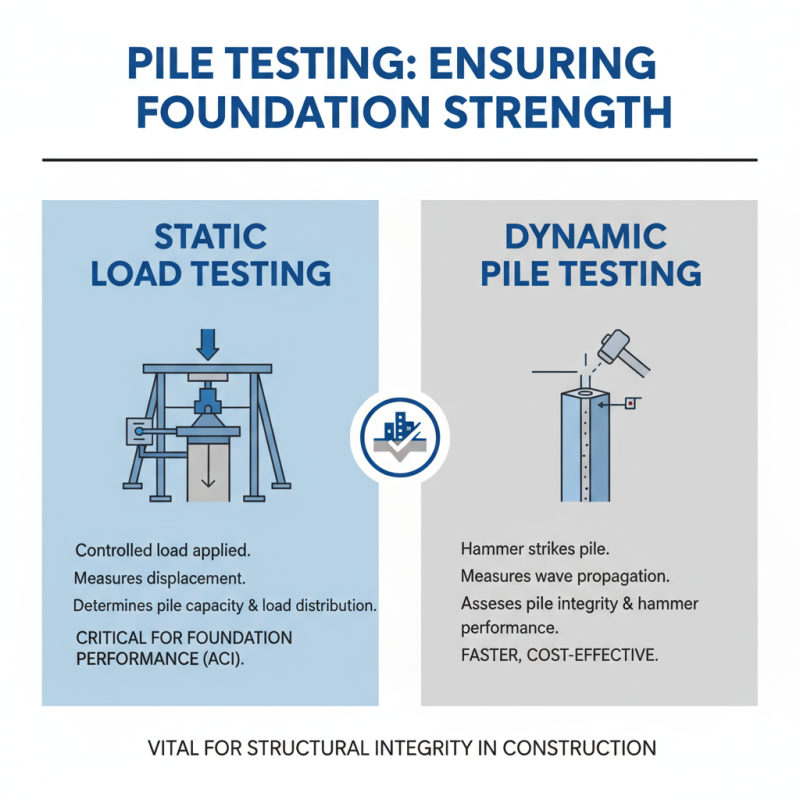

Pile testing is a vital process in ensuring the structural integrity of foundations in construction projects. There are various methods employed in pile testing, each suited for different types of assessments and site conditions. Two primary categories of pile testing methods are static and dynamic testing. Static testing, often referred to as load testing, involves applying a controlled load to the pile and measuring the resultant displacement. According to the American Concrete Institute, static load tests are instrumental in determining the pile’s capacity and load distribution, which provides critical insights into foundation performance.

On the other hand, dynamic testing includes methods such as the Pile Driving Analyzer (PDA) and sonic testing. Dynamic load testing is particularly useful during construction because it provides immediate feedback on pile performance. A study published by the Geotechnical Engineering Division indicates that dynamic methods can evaluate the soil-pile interaction in real-time, which is essential for understanding the behavior of foundations under loads. Furthermore, high-strain dynamic testing is increasingly favored due to its non-destructive nature and efficiency in identifying potential issues without disrupting ongoing construction activities.

Each methodology contributes uniquely to assessing the performance of piles. The choice between static and dynamic testing often depends on project requirements, soil conditions, and the type of structure involved. Understanding these methods not only helps in ensuring safety and compliance but also aids in optimizing costs and resources throughout a project’s lifecycle.

How Pile Testing Equipment Measures Load Capacity and Integrity

Pile testing equipment plays a crucial role in assessing the load capacity and integrity of foundation piles. By utilizing various methods such as static and dynamic loading tests, engineers can determine the maximum weight a pile can withstand without failure. Static load tests involve gradually applying weight to the pile and measuring its displacement, providing clear data on both the maximum load-bearing capacity and the pile's performance under pressure. This method allows for a comprehensive understanding of load distribution and potential settlement issues.

On the other hand, dynamic load testing uses equipment to generate impacts that simulate real-world conditions. This technique measures the response of the pile as it is struck, helping to evaluate its integrity and structural condition without extensive excavation. Key parameters such as driving velocity and energy transfer are analyzed to predict how well the pile will perform under additional loads. Together, these testing methods ensure that the foundations constructed are not only capable of supporting the intended structures above but also maintain long-term safety and stability in various environmental conditions.

Factors Influencing the Results of Pile Testing Procedures

The results of pile testing procedures are influenced by various factors that must be carefully considered to ensure accurate assessments of a structure's integrity. One primary factor is the geological conditions of the site. Variations in soil type, density, and moisture content can significantly affect the load-bearing capacity of piles. For instance, certain soil types, such as clay, may exhibit different resistance levels under load compared to sandy soils, leading to varied test results. Moreover, the presence of groundwater can alter soil behavior, altering the bearing capacity and affecting the performance of the pile.

Another crucial factor is the method of pile installation, which can impact the test outcomes. Techniques such as driven piles versus drilled shafts result in different levels of soil disturbance and bonding characteristics. Additionally, the age of the piles and the curing time post-installation can play a role in the testing results. Piles that have had sufficient time to settle may demonstrate enhanced load transfer abilities. Environmental factors, such as temperature and weather conditions during testing, can also influence the measurements taken. All these elements combined highlight the complexity of interpreting pile testing results, necessitating a comprehensive understanding of both the external factors and the methodologies employed.

What is Pile Testing Equipment and How Does it Ensure Structural Integrity - Factors Influencing the Results of Pile Testing Procedures

| Testing Method | Equipment Used | Key Factors Influencing Results | Typical Applications |

|---|---|---|---|

| Static Load Testing | Load Cells, Hydraulic Jacks | Soil Properties, Load Distribution | High-Rise Buildings, Bridges |

| Dynamic Load Testing | Drop Weight System, Accelerometers | Material Properties, Impact Forces | Foundations, Pile Groups |

| Transferring Load Tests | Load Transfer Devices | Installation Quality, Load Conditions | Deep Foundations, Retaining Walls |

| Integrity Testing | Sonar Equipment, Low Strain Impact | Concrete Quality, Internal Flaws | Quality Assurance, Retrofitting |

The Importance of Pile Testing in Construction and Engineering Projects

Pile testing is a critical aspect of construction and engineering projects, ensuring that the foundational elements of structures can withstand various stresses and loads. According to a report by the American Society of Civil Engineers (ASCE), improper pile design or installation can lead to significant structural failures, which not only endanger lives but also incur substantial financial costs for repairs and liabilities. Pile testing serves to assess the load-bearing capacity and integrity of piles before they are subjected to actual operational loads, thus minimizing risks associated with ground instability and structural collapse.

In recent years, the adoption of advanced pile testing techniques, such as dynamic load testing and static load testing, has become increasingly vital. Data from the International Society for Soil Mechanics and Geotechnical Engineering indicates that approximately 30% of construction failures are attributed to inadequate foundation support. Implementing thorough pile testing protocols can significantly reduce this percentage by verifying that piles meet or exceed safety and performance standards. For instance, a case study from a major infrastructure project highlighted that pre-installation pile testing led to a 25% increase in reliability compared to projects where testing was not conducted. This underscores the importance of integrating robust testing methodologies in the early stages of construction to safeguard structural integrity and ensure the longevity of the project.

Pile Testing Equipment and Its Role in Ensuring Structural Integrity

This chart illustrates the importance levels of various pile testing methods, highlighting their relevance in ensuring the structural integrity of construction and engineering projects. The static load test ranks the highest, demonstrating its critical role in verifying the load-bearing capacity of piles.

Related Posts

-

What is Meter Test Equipment? A Complete Guide to Understanding Its Importance and Usage

-

The Future of Impact Testing Technology: Innovations Shaping Enhanced Durability Standards

-

What is a Depth Tester and How Does it Work in Different Applications

-

What is Field Test Equipment and How It Benefits Your Testing Process

-

Water Testing Meter Innovations and Market Trends at the 138th Canton Fair in 2025

-

The Ultimate Guide to Choosing the Best Quality Testing Equipment for Your Business