Top Quality Testing Equipment for Accurate Results?

In the realm of manufacturing and testing, quality testing equipment plays a vital role. It ensures that products meet rigorous standards. Accurate results depend on the tools we use. Without reliable equipment, mistakes can occur, leading to significant issues down the line.

Investing in top-quality testing equipment is essential. It can save time and resources, while providing peace of mind. Some may underestimate the impact of using subpar tools. However, the consequences of poor testing can be severe. Inconsistent results can harm a company's reputation.

Moreover, choosing the right equipment requires careful consideration. Not all tools suit every application. Users should reflect on their specific needs and requirements. Failure to do so may result in inadequate testing. Quality is not just a buzzword; it is a necessity for successful outcomes.

Understanding the Importance of Quality Testing Equipment

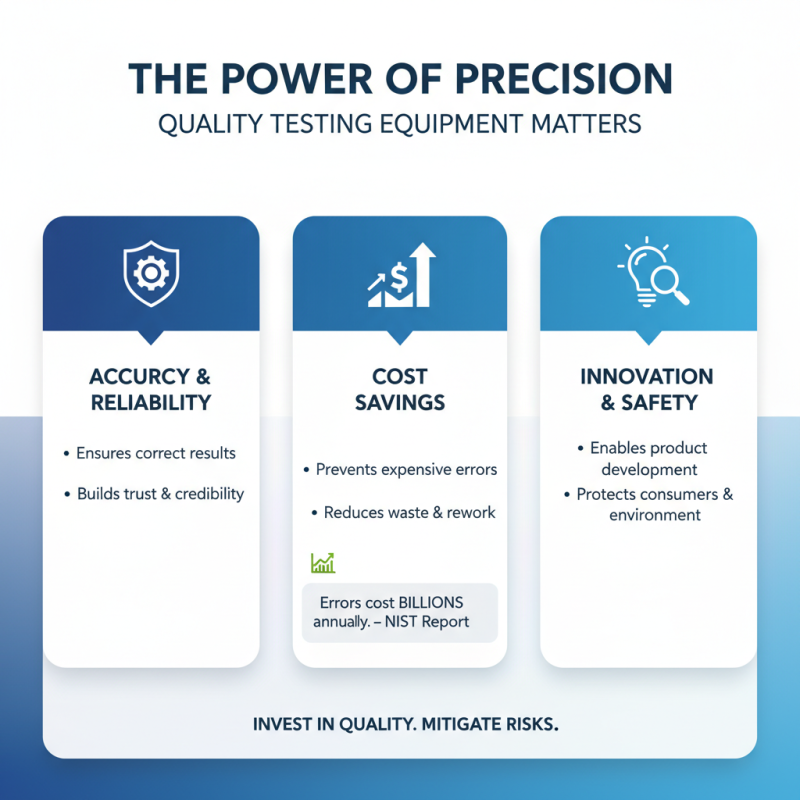

Quality testing equipment plays a critical role in ensuring accurate results across industries. According to a report by the National Institute of Standards and Technology, inaccuracies in testing can lead to costly errors, with estimates suggesting financial losses reaching billions annually. Ensuring high-quality equipment can mitigate these risks significantly.

Maintaining precision in testing processes depends heavily on the tools used. A study by the American Society for Quality found that almost 40% of companies reported issues with equipment leading to faulty results. This indicates a pressing need for businesses to evaluate their testing equipment regularly. Investing in reliable tools is essential, but it’s not just about the cost. The durability and calibration of testing devices also factor into their effectiveness.

Additionally, human oversight remains an issue. Operators may misuse or fail to calibrate equipment properly. Misunderstandings surrounding equipment capabilities can lead to flawed results. According to recent surveys, 25% of technicians admit to skipping critical maintenance steps. It’s crucial for organizations to prioritize training and adhere to stringent maintenance schedules to enhance outcome reliability.

Key Features to Look for in Accurate Testing Tools

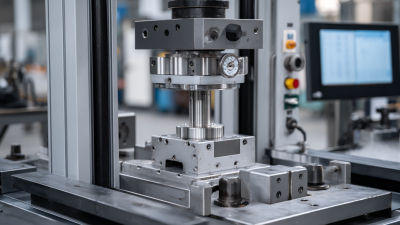

When searching for testing equipment, accuracy is essential. The right tools can make a significant difference in results. First, consider calibration features. Equipment should calibrate easily and accurately. This ensures reliability over time. Many testers fail due to neglect in this area. It's vital to regularly check calibration to avoid misleading data.

Another key feature is durability. High-quality tools withstand repeated use. They should resist wear and tear. Equipment made of strong materials lasts longer. When testing equipment breaks down, it wastes time and resources. Look for warranties that cover defects.

Portability should also be considered. Testing tools that are easy to carry help in different settings. Compact designs save space and improve accessibility. It's important to think about how you'll use the equipment. Choose tools that fit your workflow and environment. Finding an ideal balance may take time. Sometimes, more features can complicate use rather than enhance it.

Types of Testing Equipment for Different Industries

In various industries, testing equipment plays a crucial role in achieving accurate results. Quality control in manufacturing relies heavily on specific tools. For instance, a caliper measures dimensions with precision, ensuring parts fit perfectly. In the pharmaceuticals field, analytical balances are essential for weighing compounds accurately. These devices help maintain consistency in drug formulations, which is vital for patient safety.

Construction and civil engineering require different types of equipment. Soil testing is often done with proctors. These tests assess moisture content and density, impacting the structural integrity of buildings. Additionally, hardness testers are popular in metalworking, determining the durability of materials. However, improper use of these tools can lead to erroneous results and costly mistakes.

Moreover, industries face a constant challenge in keeping equipment calibrated. Outdated tools may provide inaccurate readings, affecting quality assurance. Regular maintenance checks are necessary, yet often neglected. This oversight can have significant consequences. Continuous training for staff using these instruments is just as important. A skilled operator can maximize the potential of testing equipment, leading to better outcomes and reduced errors.

Best Practices for Maintaining and Calibrating Testing Devices

Maintaining and calibrating testing devices is vital for achieving accurate results. A study from the National Institute of Standards and Technology (NIST) revealed that 30% of testing errors stem from equipment that is improperly calibrated. Regular checks and maintenance help prevent such inaccuracies. Calibration intervals should be based on usage frequency and environmental conditions. For most devices, recalibrating every six months is generally recommended.

Proper cleaning and handling of testing equipment also play critical roles. Dust and residue can interfere with measurements. In one case, a laboratory found that particles on equipment led to an error margin exceeding 15%. Daily visual inspections can identify visible issues before they escalate. Simple steps can ensure longevity and performance but are often overlooked.

Documentation of maintenance and calibration is another essential practice. This creates a reliable history that assists in troubleshooting and validating results. The American National Standards Institute (ANSI) advises not only to log maintenance but also to evaluate the effectiveness of procedures regularly. Yet, many labs fail to perform these reviews. Investing time in these processes is not just a suggestion; it's a necessity for quality assurance.

Testing Equipment Accuracy Over Time

Emerging Technologies in Testing Equipment for Enhanced Accuracy

Emerging technologies in testing equipment are transforming the landscape of accuracy in various industries. For instance, advancements in artificial intelligence are enabling more precise data analysis. Recent reports indicate that AI can improve testing accuracy by up to 30%. This shift enhances the reliability of test results, which is crucial in sectors like healthcare and manufacturing.

Moreover, the integration of IoT (Internet of Things) in testing devices allows for real-time data monitoring. Devices equipped with IoT capabilities can track changes continuously. According to industry studies, real-time monitoring can reduce error rates by approximately 25%. These technologies enable professionals to respond swiftly to anomalies and make informed decisions.

Tips: Invest in equipment that supports these emerging technologies. Periodic training on new tools increases efficacy. Remember, even the best technology has limitations. Not every test will yield perfect results, so always analyze data critically and be prepared for unexpected outcomes. Embracing these innovations can lead to significant improvements, but caution is essential for overall success.

Top Quality Testing Equipment for Accurate Results

| Test Equipment Type | Measurement Range | Accuracy (% Full Scale) | Technology Used |

|---|---|---|---|

| Digital Multimeter | 0-1000 V | 0.5% | Digital Signal Processing |

| Oscilloscope | 0-100 MHz | 1% | High-speed Sampling |

| Thermometer | -200°C to 1200°C | 0.1% | Infrared Technology |

| Caliper | 0-300 mm | 0.02 mm | Digital Measurement |

Related Posts

-

How to Test a Meter for Accuracy and Reliability?

-

5 Reasons Why the Tester Line is the Best Choice for Your Production Needs

-

Innovative Solutions for Precision Line Testers

-

What is Pile Testing Equipment and How Does it Ensure Structural Integrity

-

Understanding the Importance of Impact Tester in Modern Manufacturing Processes

-

The Ultimate Guide to Choosing the Best Phone Testing Equipment for Your Needs