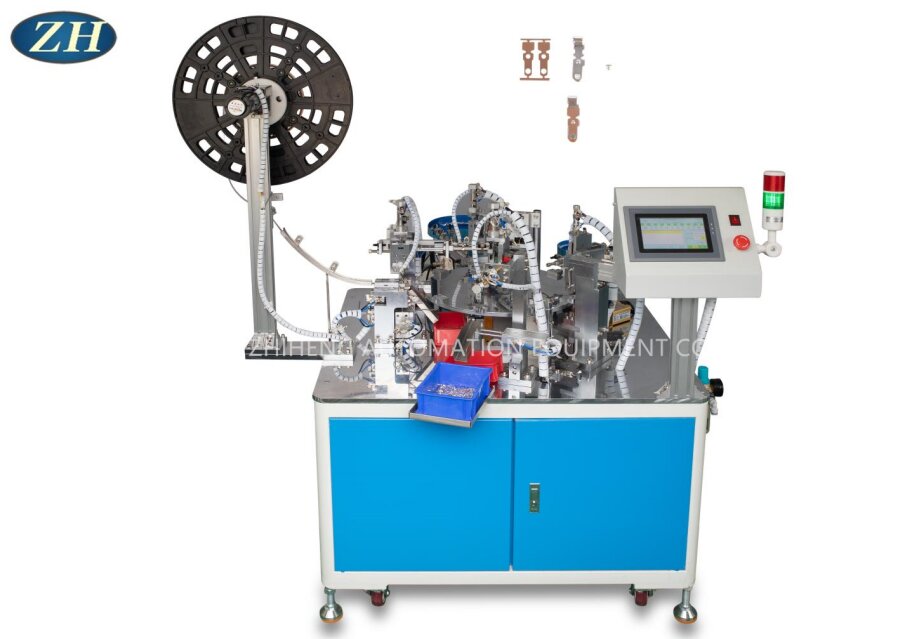

Belt Feeder Riveting Machine

2025-03-28

1, Equipment overview

Belt Feeder Riveting Machine, as the name suggests, is a combination of belt conveyor and riveting functions of automated equipment. It enables continuous material strips to be firmly connected together through rivets at predetermined intervals and positions to form the required product or component. This equipment is widely used in the manufacturing industry, especially in environments that require continuous and efficient production, such as automotive manufacturing, electronic appliances, construction machinery and other fields.

2, Working principle

1.Conveyor belt: The conveyor belt is continuously and smoothly transported to the riveting station through the conveyor mechanism (such as rollers, chains, etc.). During the conveying process, the speed and position of the material belt can be precisely adjusted by the control system.

2.Rivet positioning and conveying: Before the material belt reaches the riveting station, the rivet is accurately transported to the predetermined position of the riveting head through the automatic feeding device. The feeding device usually adopts vibrating disk, linear vibrator, etc., which can ensure continuous and stable supply of rivets.

3.Riveting operation: When the material belt and rivets have reached the predetermined position, the riveting head exerts pressure on the material belt under the action of the power device (such as the cylinder, hydraulic cylinder, etc.), and presses the rivets into the material belt to complete the riveting operation. During the riveting process, the control system monitors the riveting quality in real time to ensure the firmness and consistency of each riveting point.

4.Finished product output: After riveting is completed, the material tape continues to be transported out of the equipment to form the desired product or part. At the same time, the control system records the position and status of each riveting point for subsequent quality tracing and analysis.

3, Equipment characteristics

1.High degree of automation: the material riveting machine can achieve automatic feeding, automatic riveting and automatic detection and other functions, greatly reducing manual intervention, improve production efficiency and product quality.

2.High production efficiency: Due to the use of continuous belt conveyor and efficient riveting technology, the Belt Feeder Riveting Machine can achieve high-speed and stable production to meet the needs of large-scale production.

3.Stable riveting quality: Through precise control system and advanced riveting technology, the material Belt Feeder Riveting Machine can ensure the fastness and consistency of each riveting point, improving the reliability and durability of the product.

4.Strong adaptability: The material Belt Feeder Riveting Machine can adapt to different materials, thickness and width of the material belt, as well as different specifications and shapes of the rivets, with strong flexibility and versatility.

5.Easy to operate: the material riveting machine usually adopts a humanized operating interface and control system, so that the operator can easily grasp the operation and maintenance methods of the equipment.

4, Application field

1.Automotive manufacturing: Used for riveting body parts, interior trim parts, etc.

2.Electronic appliances: Used for riveting electronic components, electrical housings, etc.

3.Construction machinery: used for riveting mechanical parts, structural parts, etc.

4.Aerospace: Used for riveting aircraft parts, satellite parts, etc.

5, Care and maintenance

1.Clean the equipment: regularly clean the surface and inside of the equipment, remove dust, oil and other debris, and keep the equipment clean and hygienic.

2.Check parts: Regularly check the various parts of the equipment, such as conveying mechanism, riveting head, power plant, etc., to ensure their normal operation and no damage.

3.Lubricating parts: Regular lubrication of the parts that need to be lubricated, such as the roller of the conveying mechanism, the chain, etc., to reduce friction and wear and extend the service life.

4.Replacement of wearing parts: Timely replacement of wearing parts with serious wear, such as the belt of the conveyor mechanism, the riveting die of the riveting head, etc., to ensure the normal operation and riveting quality of the equipment.

5.Train operators: Train operators regularly to improve their operation skills and maintenance awareness to ensure the correct use and timely maintenance of equipment.

In summary, the material Belt Feeder Riveting Machine is an efficient and stable automatic riveting equipment, which is widely used in the manufacturing field. In order to ensure its normal operation and extend its service life, regular maintenance and maintenance are required.